Steel production represents one of the most critical industrial processes in modern manufacturing, with millions of tons processed annually across global facilities. The transformation of raw steel into high-performance materials requires precise control over multiple variables, with heat treatment serving as a fundamental cornerstone that determines the final mechanical properties and durability of steel products. This controlled heating and cooling process has revolutionized how manufacturers achieve specific material characteristics, enabling the production of everything from automotive components to aerospace-grade steel alloys. Understanding the comprehensive benefits of heat treatment in steel production provides valuable insights into why this process remains indispensable across numerous industrial applications.

Fundamental Principles of Steel Heat Treatment

Temperature Control and Phase Transformations

The success of heat treatment relies heavily on precise temperature control throughout the heating and cooling cycles. Steel undergoes distinct phase transformations at specific temperature ranges, with austenite formation typically occurring between 720°C and 850°C depending on the carbon content. These transformations fundamentally alter the crystal structure of steel, creating opportunities for manufacturers to manipulate grain size, hardness, and overall mechanical properties. Modern heat treatment facilities employ sophisticated temperature monitoring systems to ensure consistent results across large production batches.

Cooling rates play an equally important role in determining final material properties. Rapid cooling through quenching can produce extremely hard martensitic structures, while controlled slow cooling allows for the formation of softer, more ductile phases like ferrite and pearlite. This precise control over cooling parameters enables manufacturers to achieve targeted material specifications for diverse applications ranging from cutting tools to structural components.

Atmospheric Environment Management

The atmospheric environment during heat treatment significantly impacts surface quality and material integrity. Controlled atmospheres prevent oxidation and decarburization, which can compromise surface hardness and dimensional accuracy. Protective atmospheres typically consist of nitrogen, hydrogen, or carbon monoxide mixtures that create reducing conditions around the steel components. This environmental control ensures that beneficial surface properties are maintained throughout the heating process.

Advanced heat treatment facilities often incorporate vacuum furnaces for critical applications requiring absolute atmospheric control. These systems eliminate the risk of contamination and allow for precise carbon potential management, resulting in superior surface finish and enhanced material performance. The investment in atmospheric control technology directly translates to improved product quality and reduced post-processing requirements.

Mechanical Property Enhancement Through Heat Treatment

Hardness and Wear Resistance Improvements

One of the most significant benefits of heat treatment involves the dramatic improvement in hardness and wear resistance characteristics. Through processes like hardening and tempering, steel components can achieve hardness levels ranging from 30 to 65 HRC, depending on carbon content and specific treatment parameters. This enhanced hardness directly translates to improved wear resistance, making treated components suitable for high-stress applications in mining equipment, automotive engines, and industrial machinery.

The relationship between hardness and wear resistance follows predictable patterns that allow engineers to specify exact treatment protocols for desired performance outcomes. Surface hardening techniques like case hardening create a hard exterior shell while maintaining a tough, ductile core, providing optimal performance for components subjected to both impact loading and surface wear. This dual-property approach maximizes component longevity while maintaining structural integrity under dynamic loading conditions.

Strength and Toughness Optimization

Heat treatment enables precise control over the balance between strength and toughness, two properties that traditionally exist in inverse relationship. Through carefully controlled tempering processes, manufacturers can achieve optimal combinations of tensile strength and impact resistance for specific applications. High-strength steels used in construction and automotive applications often require yield strengths exceeding 700 MPa while maintaining adequate ductility for forming operations.

Advanced heat treatment techniques like austempering and martempering provide alternative pathways to achieve superior strength-toughness combinations. These processes avoid the brittleness associated with conventional quenching while still providing significant strength improvements over annealed conditions. The resulting materials exhibit enhanced fatigue resistance and improved fracture toughness, making them ideal for critical safety applications.

Microstructural Refinement and Grain Control

Grain Size Manipulation Benefits

Heat treatment provides unprecedented control over grain size and distribution within steel microstructures. Fine-grained steels typically exhibit superior mechanical properties compared to coarse-grained alternatives, including higher yield strength, improved toughness, and enhanced fatigue resistance. The Hall-Petch relationship demonstrates that strength increases proportionally with the inverse square root of grain size, making grain refinement a powerful tool for property enhancement.

Normalizing treatments effectively refine grain structure by heating steel above the critical temperature and allowing air cooling. This process eliminates casting defects, homogenizes chemical composition, and creates uniform fine-grained microstructures throughout the component. The resulting improvement in mechanical properties often eliminates the need for more expensive alloying additions, providing both performance and economic benefits.

Elimination of Internal Stresses

Manufacturing processes like welding, machining, and forming introduce significant internal stresses that can compromise component performance and dimensional stability. Stress relief heat treatment cycles effectively eliminate these residual stresses through controlled heating to moderate temperatures followed by slow cooling. This process prevents warping, cracking, and premature failure during service while improving machinability for subsequent operations.

The benefits of stress relief extend beyond dimensional stability to include improved fatigue life and reduced susceptibility to stress corrosion cracking. Components subjected to cyclic loading particularly benefit from stress relief treatments, as residual stresses can significantly accelerate crack initiation and propagation. The relatively low temperatures required for stress relief make this treatment economically attractive for large structural components.

Economic and Production Efficiency Advantages

Cost-Effective Property Enhancement

Heat treatment represents one of the most cost-effective methods for achieving significant property improvements in steel components. Compared to expensive alloying additions or alternative materials, heat treatment can increase component performance by 200-500% for a fraction of the material cost. This economic advantage becomes particularly important in competitive markets where performance requirements continue to increase while cost pressures intensify.

The ability to use lower-cost base materials and achieve premium performance through heat treatment enables manufacturers to optimize their material specifications and reduce overall production costs. Carbon steels subjected to appropriate heat treatment can often replace more expensive alloy steels while meeting identical performance requirements. This material substitution capability provides significant competitive advantages in cost-sensitive applications.

Production Flexibility and Customization

Modern heat treatment facilities offer exceptional flexibility in processing diverse component geometries and achieving varied property combinations within single production runs. Computer-controlled furnaces enable precise implementation of complex thermal cycles, allowing manufacturers to customize material properties for specific customer requirements. This flexibility reduces inventory requirements and enables just-in-time production strategies that minimize working capital requirements.

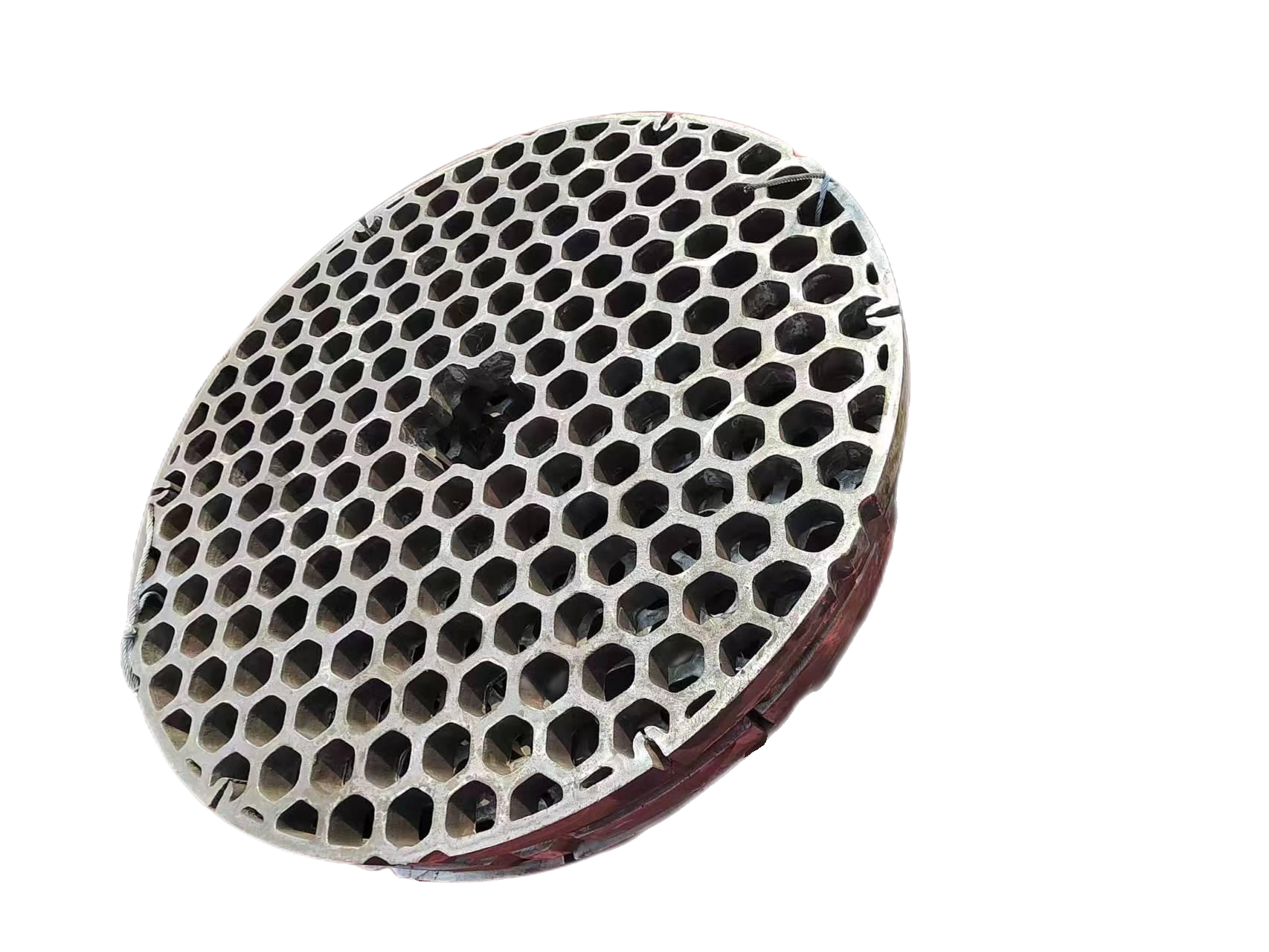

Batch processing capabilities allow efficient treatment of multiple components simultaneously, significantly reducing per-unit processing costs. Advanced furnace designs incorporate uniform heating zones and precise atmosphere control to ensure consistent results across entire batches. This production efficiency makes heat treatment economically viable even for moderate-volume applications where alternative processing methods would be prohibitively expensive.

Quality Control and Repeatability Benefits

Process Monitoring and Documentation

Contemporary heat treatment operations incorporate sophisticated monitoring and control systems that provide real-time process documentation and quality assurance. Digital temperature recorders, atmosphere analyzers, and automated cooling systems ensure that each component receives precisely specified treatment parameters. This level of process control enables manufacturers to achieve consistent results and provide comprehensive documentation for quality certification requirements.

Statistical process control techniques applied to heat treatment data enable continuous improvement and optimization of treatment parameters. Trend analysis of temperature profiles, cooling rates, and resulting mechanical properties helps identify process variations before they impact product quality. This proactive approach to quality control minimizes rejected components and reduces overall production costs while maintaining customer satisfaction.

Traceability and Certification Compliance

Heat treatment processes generate comprehensive records that support traceability requirements in regulated industries like aerospace, automotive, and medical devices. Detailed documentation of time, temperature, atmosphere, and cooling parameters provides essential information for failure analysis and process optimization. This documentation capability becomes increasingly important as quality standards continue to evolve and customer requirements become more stringent.

Certification to international standards like ISO 9001, AS9100, and NADCAP requires demonstrable process control and documentation capabilities that modern heat treatment facilities readily provide. The ability to maintain certified processes gives manufacturers access to premium markets where quality requirements justify higher pricing structures. This certification capability often becomes a key differentiator in competitive bidding situations.

Environmental and Safety Considerations

Energy Efficiency Improvements

Modern heat treatment technologies incorporate significant energy efficiency improvements that reduce operating costs and environmental impact. High-efficiency furnace designs, waste heat recovery systems, and optimized heating cycles can reduce energy consumption by 30-50% compared to older technologies. These efficiency gains directly translate to reduced operating costs and improved environmental compliance.

Advanced furnace controls enable precise heating strategies that minimize energy waste while ensuring complete and uniform heating of components. Variable frequency drives, improved insulation systems, and recuperative burners capture and reuse waste heat that would otherwise be lost to the atmosphere. These technological improvements make heat treatment increasingly attractive from both economic and environmental perspectives.

Emissions Reduction and Compliance

Contemporary heat treatment facilities implement comprehensive emissions control systems that minimize environmental impact while maintaining regulatory compliance. Thermal oxidizers, scrubber systems, and improved combustion controls significantly reduce air pollutant emissions compared to older facilities. These environmental improvements support corporate sustainability initiatives while ensuring continued regulatory compliance.

The adoption of cleaner fuel sources and improved combustion efficiency reduces greenhouse gas emissions associated with heat treatment operations. Natural gas substitution for fuel oil, oxygen-enriched combustion, and waste heat recovery systems contribute to overall emissions reduction while often providing operating cost benefits. These environmental improvements enhance corporate reputation and support long-term business sustainability.

FAQ

What types of steel benefit most from heat treatment processes

Medium and high-carbon steels typically show the most dramatic improvements from heat treatment, as their carbon content enables significant hardness and strength gains through martensitic transformations. Low-alloy steels also respond well to heat treatment, achieving excellent strength-to-weight ratios for automotive and structural applications. Tool steels represent another category that relies heavily on heat treatment to achieve the extreme hardness and wear resistance required for cutting and forming operations. Even low-carbon steels benefit from normalizing treatments that refine grain structure and improve mechanical properties, though the improvements are more modest compared to higher-carbon grades.

How does heat treatment affect the dimensional stability of steel components

Properly executed heat treatment generally improves dimensional stability by relieving internal stresses introduced during manufacturing processes like welding, machining, and forming. Stress relief treatments prevent warping and distortion during subsequent processing or service conditions. However, the heat treatment process itself can introduce dimensional changes due to phase transformations and thermal expansion effects. Careful fixture design and controlled cooling rates minimize these changes, while double tempering treatments help stabilize dimensions for precision applications. Modern heat treatment facilities use predictive modeling to compensate for expected dimensional changes, ensuring that finished components meet tight tolerance requirements.

What safety considerations are important in heat treatment operations

Heat treatment operations involve significant safety risks related to high temperatures, toxic atmospheres, and potential fire hazards that require comprehensive safety protocols. Personal protective equipment including heat-resistant clothing, respiratory protection, and eye protection are essential for worker safety. Proper ventilation systems prevent accumulation of toxic gases like carbon monoxide, while fire suppression systems protect against combustible atmosphere ignition. Regular training on emergency procedures, proper handling of hot materials, and recognition of hazardous conditions helps prevent accidents and ensures regulatory compliance. Automated material handling systems reduce worker exposure to high-temperature environments while improving process consistency.

How do modern heat treatment facilities ensure consistent quality across production batches

Contemporary heat treatment facilities employ sophisticated process control systems that monitor and adjust critical parameters in real-time to maintain consistency across production batches. Computerized temperature controllers maintain precise heating and cooling profiles, while atmosphere monitoring systems ensure proper chemical environments throughout the treatment cycle. Statistical process control techniques analyze treatment data to identify trends and variations before they affect product quality. Regular calibration of instrumentation, preventive maintenance programs, and operator training ensure that process capabilities remain stable over time. Batch documentation systems provide complete traceability and enable continuous improvement through data analysis and process optimization.

Table of Contents

- Fundamental Principles of Steel Heat Treatment

- Mechanical Property Enhancement Through Heat Treatment

- Microstructural Refinement and Grain Control

- Economic and Production Efficiency Advantages

- Quality Control and Repeatability Benefits

- Environmental and Safety Considerations

-

FAQ

- What types of steel benefit most from heat treatment processes

- How does heat treatment affect the dimensional stability of steel components

- What safety considerations are important in heat treatment operations

- How do modern heat treatment facilities ensure consistent quality across production batches