Understanding the Ancient Art of Investment Casting in Modern Manufacturing

The intricate world of manufacturing has evolved significantly over millennia, yet some techniques remain timeless in their effectiveness. Lost wax casting services represent one such enduring method, combining ancient wisdom with modern precision to create complex metal components. This sophisticated process, also known as investment casting, continues to serve industries ranging from aerospace to jewelry making, offering unparalleled accuracy and versatility in metal fabrication.

Today's lost wax casting services have transformed from their historical roots into a highly refined industrial process. Manufacturing facilities worldwide employ this technique to produce components that demand exceptional detail and precision. The process begins with a wax pattern and culminates in a finished metal part, offering manufacturers a reliable method to create intricate designs that would be impossible or prohibitively expensive to produce through other means.

The Technical Process Behind Professional Casting

Initial Pattern Development and Wax Selection

The journey of creating precision components through lost wax casting services starts with the careful selection of wax materials. Engineers work with specialized wax compounds that possess specific melting points, hardness levels, and expansion properties. These characteristics are crucial for maintaining dimensional accuracy throughout the casting process. The pattern-making phase requires meticulous attention to detail, as any imperfection in the wax pattern will be reflected in the final metal component.

Modern lost wax casting services utilize advanced CAD technology to design patterns with unprecedented precision. This digital approach allows for rapid prototyping and pattern modification, significantly reducing the time between initial design and final production. The integration of computer-aided design has revolutionized the traditional process, enabling manufacturers to achieve tolerances as tight as ±0.005 inches in some applications.

Investment Shell Building and Material Selection

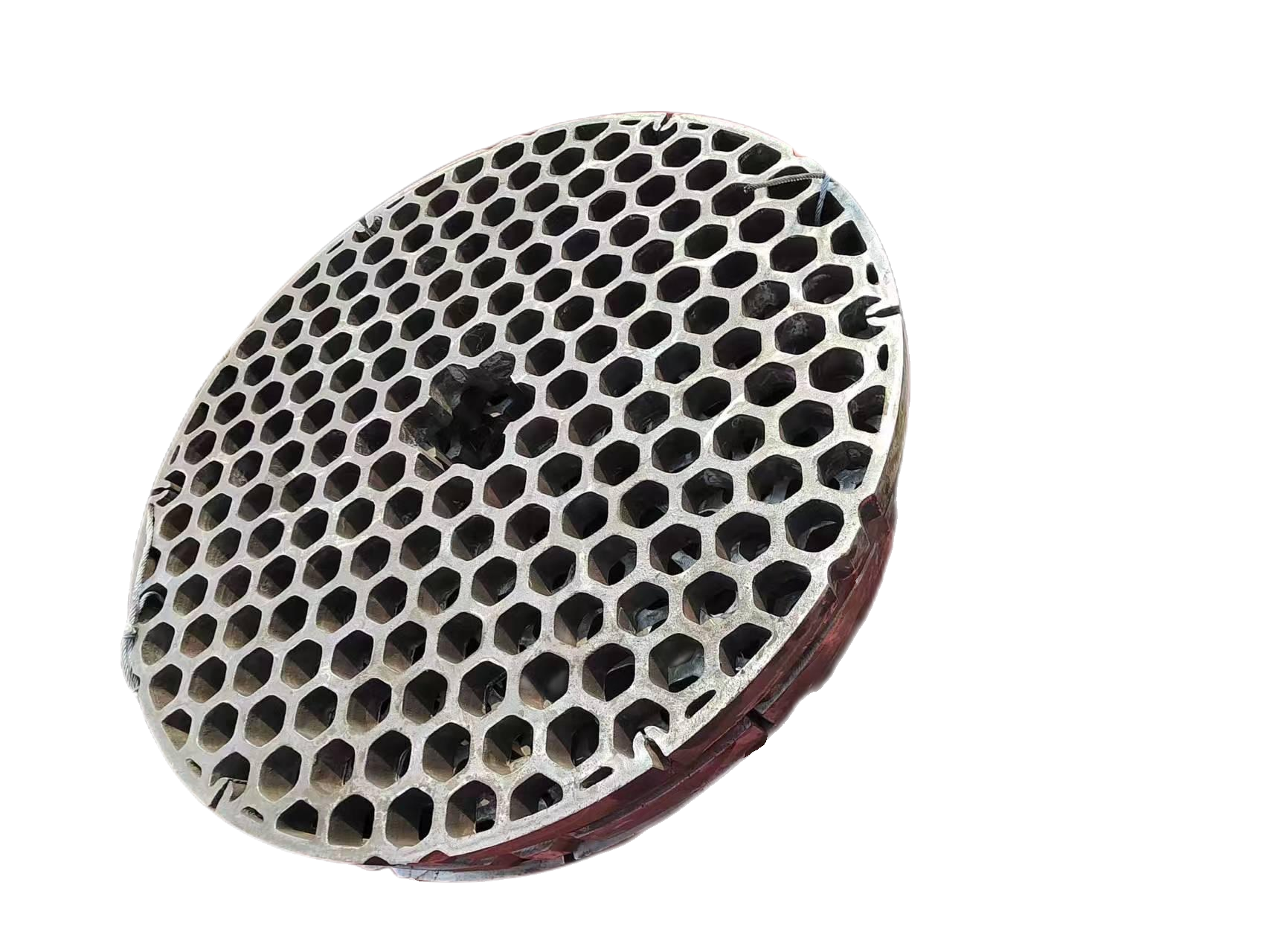

The creation of the ceramic shell represents a critical phase in professional lost wax casting services. Technicians carefully dip wax patterns into ceramic slurry and apply stucco layers, building up a robust shell that can withstand the extreme temperatures of molten metal. This multi-step process requires precise control of environmental conditions, including temperature and humidity, to ensure consistent shell quality.

Material selection for the ceramic shell depends on factors such as the intended casting metal, required surface finish, and component complexity. Advanced lost wax casting services maintain strict quality control measures during shell building, as the integrity of this ceramic mold directly impacts the quality of the final casting.

Economic Considerations and Industry Applications

Cost Analysis and Production Volume Benefits

When evaluating lost wax casting services, manufacturers must consider both initial tooling costs and long-term production economics. While the setup costs for investment casting may be higher compared to some alternative methods, the process often proves more economical when producing complex parts in medium to high volumes. The elimination of extensive machining operations and reduced material waste contribute to overall cost efficiency.

Modern lost wax casting services offer significant advantages in terms of material utilization. The process typically achieves a buy-to-fly ratio of 1.5:1 or better, meaning less raw material is wasted compared to traditional machining methods. This efficiency becomes particularly valuable when working with expensive alloys or precious metals.

Industry-Specific Applications and Advantages

The aerospace industry relies heavily on lost wax casting services for producing turbine blades, structural components, and other critical parts. The ability to cast complex internal passages and maintain tight tolerances makes investment casting ideal for these demanding applications. Similarly, the medical device industry benefits from the process's capability to produce intricate surgical instruments and implant components.

Automotive manufacturers increasingly turn to lost wax casting services for producing high-performance engine components and precision transmission parts. The process allows for the integration of multiple features into a single casting, reducing assembly requirements and improving component reliability. This consolidation of parts can lead to significant cost savings in both production and maintenance.

Quality Control and Production Optimization

Modern Inspection Methods and Quality Assurance

Leading lost wax casting services employ sophisticated quality control measures throughout the production process. Non-destructive testing methods, including X-ray inspection and fluorescent penetrant testing, ensure that each casting meets stringent quality standards. Advanced metrology equipment allows for precise dimensional verification, while material analysis confirms proper chemical composition and mechanical properties.

Quality management systems in modern casting facilities integrate real-time monitoring and data collection. This comprehensive approach enables continuous process improvement and ensures consistent product quality. Manufacturers can track key parameters throughout the casting process, from wax pattern production to final heat treatment, maintaining full traceability for each component.

Production Efficiency and Process Control

Optimizing production efficiency in lost wax casting services requires careful attention to process variables. Temperature control during wax injection, shell building, and metal pouring must be precisely maintained to ensure consistent results. Advanced facilities utilize automated systems for pattern assembly and shell dipping, reducing variation and improving throughput.

Environmental controls play a crucial role in maintaining process stability. Modern lost wax casting services invest in sophisticated HVAC systems to regulate temperature and humidity throughout their facilities. This environmental control ensures consistent shell drying times and prevents quality issues related to atmospheric variations.

Future Trends and Technological Advancements

Digital Integration and Automation

The future of lost wax casting services lies in increased digitalization and automation. Industry 4.0 principles are being applied to traditional casting processes, enabling smart manufacturing capabilities and improved process control. Machine learning algorithms help optimize process parameters, while automated handling systems reduce labor requirements and improve consistency.

Advanced simulation software allows manufacturers to predict and prevent casting defects before production begins. These digital tools enable lost wax casting services to reduce development time and improve first-time quality rates. The integration of artificial intelligence continues to enhance process control and predictive maintenance capabilities.

Sustainable Manufacturing Practices

Environmental considerations are driving innovation in lost wax casting services. Manufacturers are developing more efficient burnout processes and investigating biodegradable wax alternatives. Water-soluble core materials and recycling programs for ceramic materials demonstrate the industry's commitment to sustainability.

Energy efficiency improvements, including advanced furnace designs and heat recovery systems, help reduce the environmental impact of casting operations. Modern lost wax casting services increasingly adopt these sustainable practices while maintaining the high-quality standards their customers demand.

Frequently Asked Questions

What materials can be used in lost wax casting services?

Lost wax casting services can accommodate a wide range of metals and alloys, including stainless steel, aluminum, brass, bronze, titanium, and precious metals like gold and platinum. The choice of material depends on the specific application requirements, including mechanical properties, corrosion resistance, and cost considerations.

How long does the lost wax casting process typically take?

The timeline for lost wax casting services varies depending on part complexity, size, and quantity. A typical production cycle, from pattern making to final inspection, can range from two to six weeks. Rush services may be available for urgent requirements, though this often incurs additional costs.

What are the size limitations for lost wax casting?

While lost wax casting services can produce components ranging from a few grams to several hundred pounds, most facilities specialize in specific size ranges. Typical maximum dimensions range from 24 to 36 inches, though larger parts are possible with specialized equipment. Minimum features can be as small as 0.015 inches, depending on the design and material.