G-NiCr28W 2.4879 Fixtures for Pit Furnace

Place of Origin Jiangsu, China

Brand Name Cosil

Model Number Heat treatment tray

Material Heat-resistant Steel

Reference Standard 1.4848/1.4849/2.4879 etc.

Dimensions According to Customers' Drawings

Material Grade HF/HH/HI/HK/HE/HT/HU etc.

Application Auto, Precision, Gear,Heat-treating Industries.

Production Process Wax Lost Process, Investment Process

Working Temperature Up to 1300℃

Certification ISO9001

- Overview

- Recommended Products

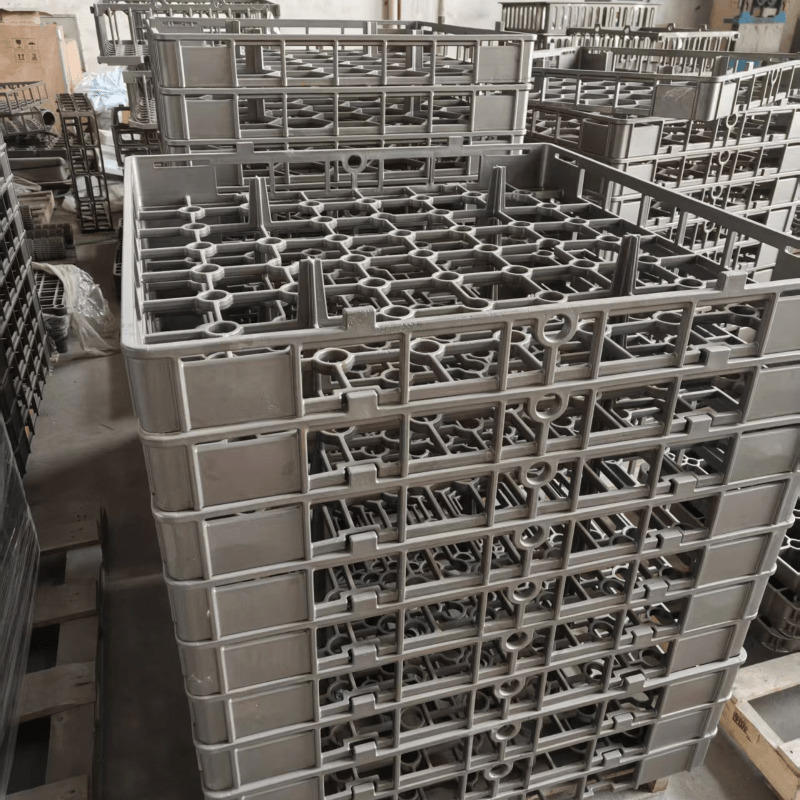

Introduction: Heat treatment tray

Lost Foam Casting: material tray, material frame, pit furnace, furnace floor;

Precision Casting: Precision castings such as material trays, material baskets, multi-purpose furnace tooling, mixing blades, etc.

Application areas: Long-term supply of cast steel parts for electric furnaces, heat treatment plants, chemical equipment plants, and metallurgical plants.

Materials include 06Cr19Ni10, Ni7N, 0Cr23Ni13, Cr25Ni20, etc., industrial furnace castings (furnace floor, furnace tube, furnace seat, material tray, material Basket, material frame seat, box, fan blade, fan shaft, etc.).

1. Production Proces:wax lost process,investment process, EPC process & sand process.

2. We make heat-resistant steel parts, such as furnace grates, furnace bed plates for cement works, steel mills.

3. We supply finished heat castings with heat-treated and machined condition if necessary

4. We can produce heat steel castings as per GB/T20878, DIN17440. DIN17224, AISI, ASTM, JIS SUH35, NF A35 - 572/584, BS970, BS 1449

Application:Auto,Precision Gear,Heat-treating industries.

Advantage:

1.Resistance to high temperature:Up to 1300℃;

2.A large number of Existing Patterns of fixture for Standard.Famous Brand Heat-treatment Furnaces.

3.Rich experience in design of Trays&Baskets to suit the secific work condition.

4.More production process available:Wax lost cast process,EPC cast process,Sand cast process.

Chemical composition:

| Composition(%) | C | Si | Mn Max. | Cr | Ni | S Max. | P Max. |

|---|---|---|---|---|---|---|---|

| 1.4823 GX40CrNiSi27-4 |

0.35-0.50 | 1.0~2.5 | 1.50 | 25.0-28.0 | 3.5-5.5 | 0.03 | 0.035 |

|

1.4825 GX25CrNiSi18-9 |

0.15-0.30 | 1.0-2.5 | 1.50 | 17.0-19.0 | 8.0-10.0 | 0.03 | 0.035 |

|

1.4826 GX40CrNiSi22-9 |

0.30-0.50 | 1.0~2.5 | 1.50 | 21.0-23.0 | 9.0-11.0 | 0.03 | 0.035 |

|

1.4832 GX25CrNiSi20-14 |

0.15-0.30 | 1.0~2.5 | 1.50 | 19.0-21.0 | 13.0-15.0 | 0.03 | 0.035 |

|

1.4837 GX40CrNiSi25-12 |

0.30-0.50 | 1.0-2.5 | 1.50 | 24.0-26.0 | 11.0-14.0 | 0.03 | 0.035 |

|

1.4848 GX40CrNiSi25-20 |

0.30-0.50 | 1.0~2.5 | 1.50 | 24.0-26.0 | 19.0-21.0 | 0.03 | 0.035 |

|

1.4865 GX40CrNiSi38-18 |

0.30-0.50 | 1.0~2.5 | 1.50 | 17.0-19.0 | 36.0-39.0 | 0.03 | 0.035 |

|

1.4857 GX40CrNiSi35-25 |

0.30-0.50 | 1.0~2.5 | 1.50 | 24.0-26.0 | 34.0-36.0 | 0.03 | 0.035 |

|

1.4855 GX30CrNiSiNb24-24 |

0.30-0.40 | 0.5-2.0 | 1.50 | 23.0-25.0 | 23.0-25.0 | 0.03 | 0.035 |

|

1.4849 GX40CrNiSNb38-18 |

0.30-0.50 | 1.0~2.5 | 1.50 | 17.0-19.0 | 36.0-39.0 | 0.03 | 0.035 |

|

1.4852 GX40CrNiSiNb35-25 |

0.35-0.45 | 1.0~2.5 | 1.50 | 24.0-26.0 | 33.0-35.0 | 0.03 | 0.035 |

| G-CoCr28 | 0.10-0.20 | 1.0~2.5 | 1.50 | 27.0-30.0 | - | 0.03 | 0.035 |

| G-CoCr28W | 0.35-0.50 | 0.5-2.0 | 1.50 | 27.0-30.0 | 47.0-50.0 | 0.03 | 0.035 |