การลงทุนและการหล่อแบบแม่นยำ จำกัด

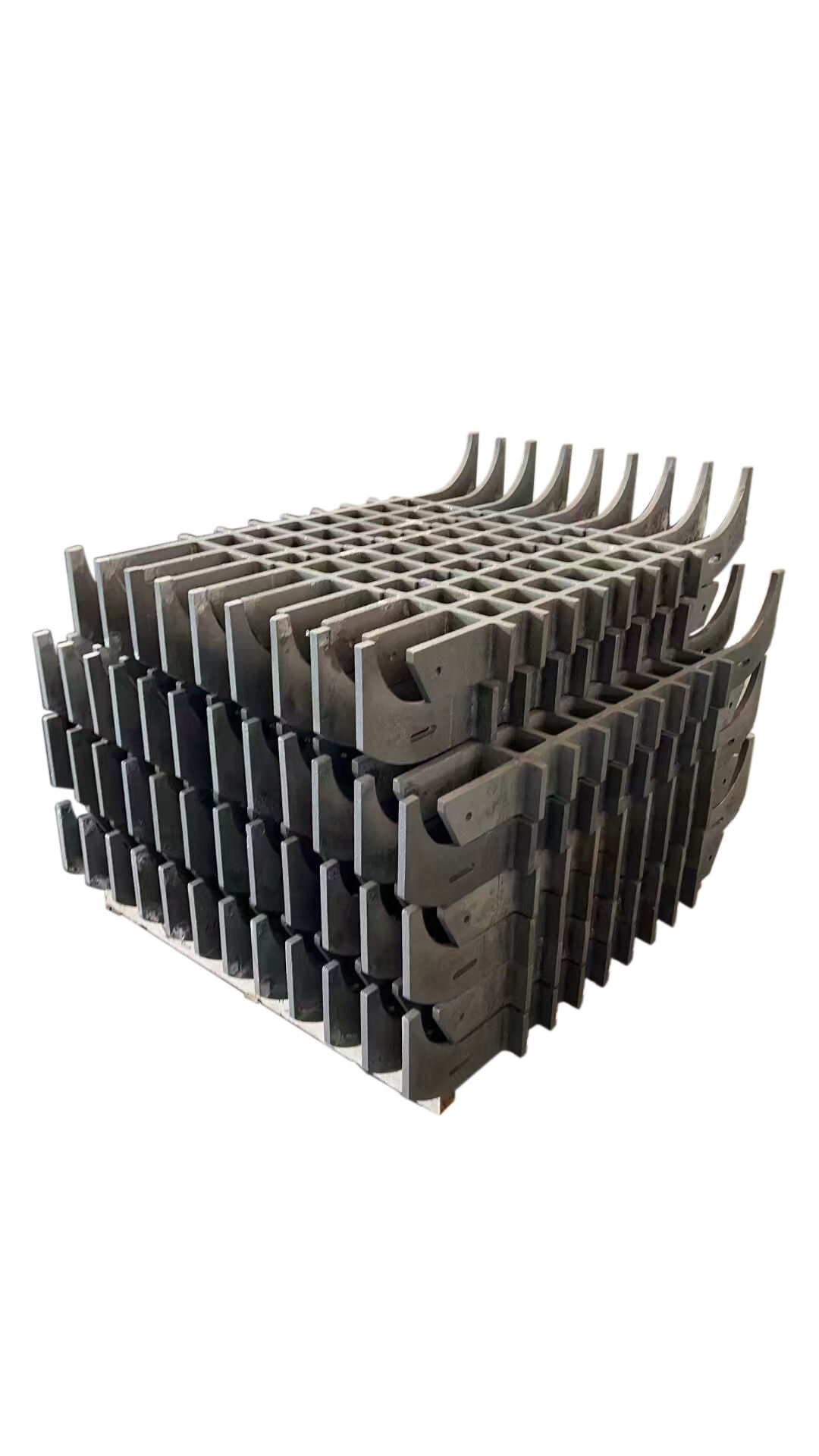

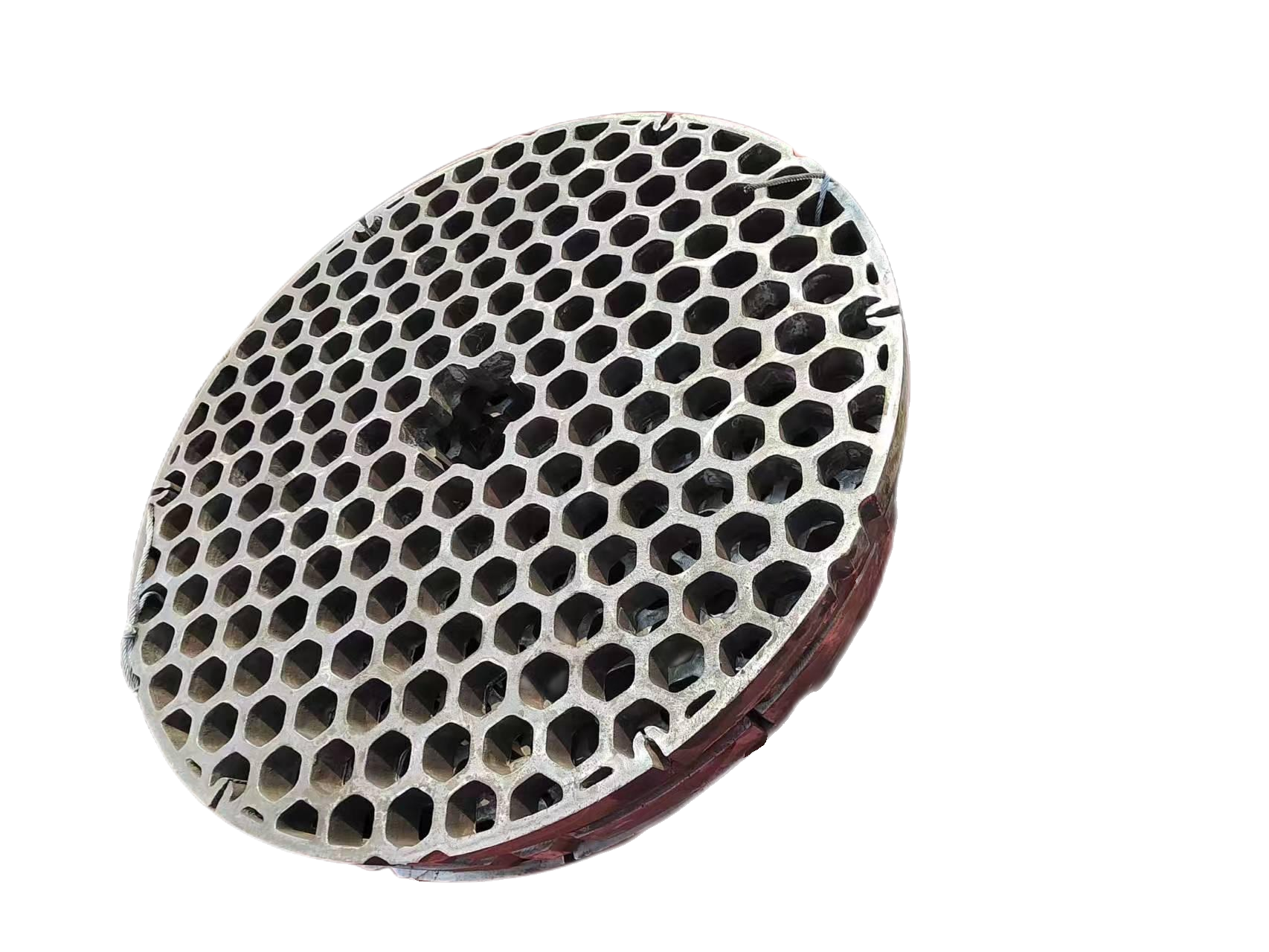

การลงทุนและการหล่อแบบแม่นยำจำกัด แสดงถึงกระบวนการผลิตที่ซับซ้อนซึ่งรวมเอาเทคนิคการหล่อแบบดั้งเดิมเข้ากับวิศวกรรมความแม่นยำสมัยใหม่ วิธีนี้เกี่ยวข้องกับการสร้างชิ้นส่วนโลหะอย่างละเอียดผ่านกระบวนการหลายขั้นตอน โดยเริ่มจากการผลิตแบบเทียนไข จากนั้นจะเคลือบแบบเหล่านี้ด้วยวัสดุเซรามิกเพื่อสร้างเปลือก ซึ่งจะถูกนำไปเผาเพื่อละลายเทียนไขออก ทิ้งไว้เพียงช่องว่างที่แม่นยำสำหรับโลหะหลอม การหล่อนี้โดดเด่นในด้านการผลิตรูปทรงที่ซับซ้อนและรายละเอียดที่ละเอียดอ่อน ซึ่งอาจยากหรือเป็นไปไม่ได้หากใช้วิธีการผลิตแบบเดิม บริษัทใช้ซอฟต์แวร์การออกแบบด้วยคอมพิวเตอร์ (CAD) และโปรแกรมจำลองล่วงหน้า เพื่อปรับปรุงการออกแบบแม่พิมพ์และพารามิเตอร์การหล่อ ทำให้มั่นใจในคุณภาพและความแม่นยำของขนาดอย่างต่อเนื่อง อุปกรณ์ในโรงงานของพวกเขามีเตาไฟฟ้า เครื่องควบคุมอุณหภูมิ และเครื่องตรวจสอบที่ทันสมัย เพื่อรักษามาตรฐานคุณภาพอย่างเข้มงวดตลอดกระบวนการผลิต เทคโนโลยีนี้มีการประยุกต์ใช้อย่างกว้างขวางในหลากหลายอุตสาหกรรม เช่น อุตสาหกรรมการบิน อุตสาหกรรมรถยนต์ อุปกรณ์ทางการแพทย์ และเครื่องจักรอุตสาหกรรม ซึ่งความแม่นยำและความน่าเชื่อถือเป็นสิ่งสำคัญ ความสามารถของบริษัทครอบคลุมถึงการหล่อโลหะและโลหะผสมหลากหลายชนิด ตั้งแต่เหล็กมาตรฐานไปจนถึงโลหะผสมพิเศษ ตอบสนองความต้องการของลูกค้าที่หลากหลาย