heat resistant steel alloys

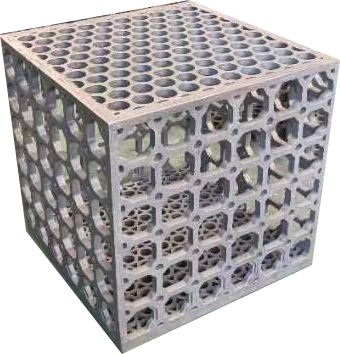

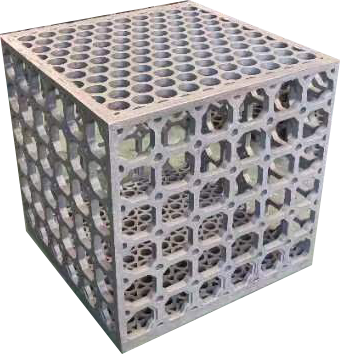

Heat resistant steel alloys represent a crucial advancement in metallurgical engineering, specifically designed to maintain their structural integrity and mechanical properties under extreme temperature conditions. These specialized alloys combine various elements such as chromium, nickel, and molybdenum to create materials that can withstand temperatures ranging from 500°C to over 1100°C while resisting oxidation, corrosion, and mechanical stress. The composition of these alloys is carefully engineered to create a protective oxide layer that prevents further degradation at high temperatures. These materials exhibit exceptional creep resistance, which is vital for components that must maintain dimensional stability under sustained high-temperature exposure. Heat resistant steel alloys find extensive applications across multiple industries, including power generation, petrochemical processing, aerospace, and industrial furnace construction. They are particularly valuable in manufacturing critical components such as turbine blades, exhaust systems, heat exchangers, and furnace parts. The ability of these alloys to maintain their properties at elevated temperatures makes them indispensable in modern industrial processes where standard steel would fail due to thermal stress or oxidation.