investment & precision castings ltd

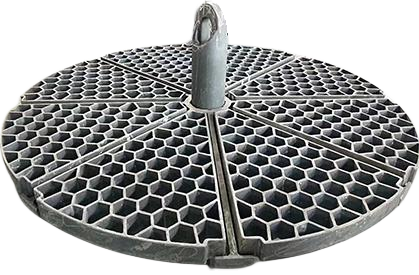

Investment & Precision Castings Ltd stands as a premier manufacturer specializing in high quality investment castings and precision components. Established with a commitment to excellence, the company leverages state of the art technology and advanced manufacturing processes to produce intricate metal components with exceptional accuracy. Their facility houses modern equipment including vacuum melting furnaces, automated wax injection systems, and sophisticated quality control instruments. The company serves diverse industries including aerospace, automotive, medical devices, and industrial machinery. Their investment casting process enables the production of complex geometries with superior surface finish and tight tolerances, while minimizing material waste and post processing requirements. The facility maintains stringent quality control measures, following international standards and certifications to ensure consistent product quality. With capabilities to work with various alloys including stainless steel, carbon steel, and superalloys, they offer comprehensive solutions from prototype development to high volume production. Their technical expertise extends to design optimization, material selection, and process engineering, providing customers with end to end support for their casting requirements.