precision investment castings limited

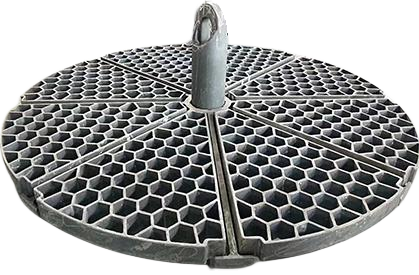

Precision Investment Castings Limited represents a state-of-the-art manufacturing facility specializing in the production of high-quality investment cast components. The company utilizes advanced casting processes that enable the creation of complex geometries with exceptional surface finishes and dimensional accuracy. Operating with cutting-edge equipment and automated systems, the facility maintains strict quality control measures throughout the entire manufacturing process, from wax pattern creation to final inspection. Their capabilities extend to producing components ranging from small intricate parts weighing just a few grams to larger castings of up to 100 pounds, serving diverse industries including aerospace, medical, automotive, and industrial equipment sectors. The facility employs sophisticated metallurgical testing procedures and advanced inspection technologies such as coordinate measuring machines (CMM) and radiographic testing to ensure product integrity. With their comprehensive in-house capabilities, including pattern making, ceramic shell building, melting, and heat treatment, they maintain complete control over the entire production process, ensuring consistent quality and shorter lead times.