designed precision castings inc

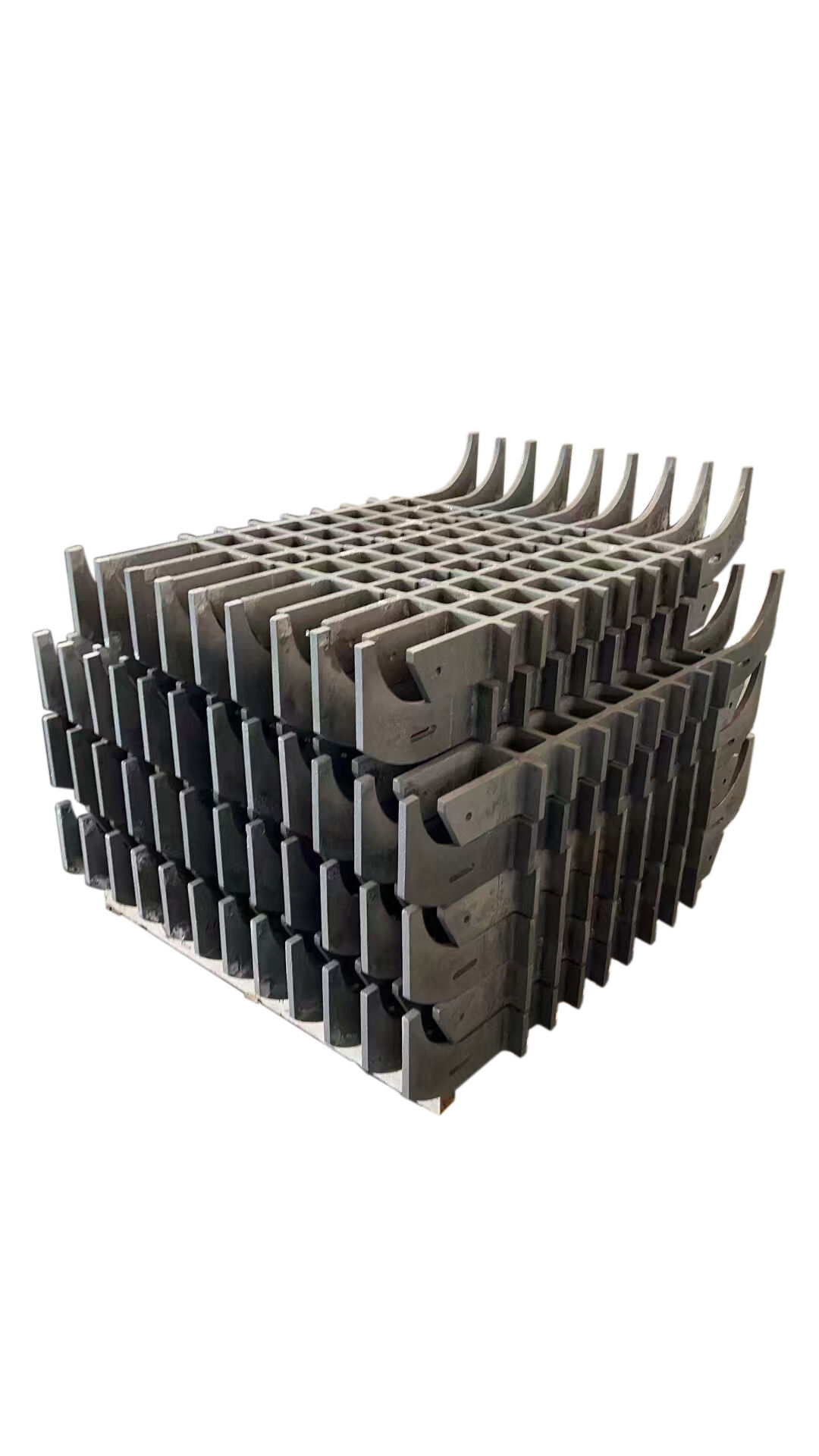

Designed Precision Castings Inc. represents a cutting-edge manufacturing facility specializing in high-quality investment casting solutions for diverse industrial applications. The company leverages advanced technology and state-of-the-art equipment to produce complex metal components with exceptional dimensional accuracy and surface finish. Their manufacturing process incorporates computer-aided design (CAD) systems, automated wax pattern production, and precise metal pouring techniques to ensure consistent quality across all production runs. The facility maintains strict quality control measures, including real-time monitoring systems and comprehensive testing protocols, to meet or exceed industry standards. With capabilities to work with various alloys including stainless steel, aluminum, and specialized superalloys, the company serves multiple sectors such as aerospace, automotive, medical equipment, and industrial machinery. Their innovative approach combines traditional investment casting expertise with modern automation and digital manufacturing principles, enabling them to handle both small-batch specialty items and high-volume production runs efficiently. The facility's commitment to sustainability is evident in their implementation of energy-efficient processes and environmentally conscious waste management systems.