precision castings & machining

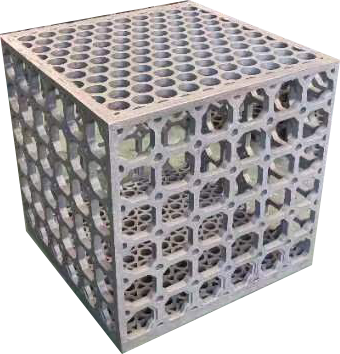

Precision castings and machining represent a sophisticated manufacturing process that combines traditional casting methods with advanced machining techniques to produce highly accurate components. This integrated approach allows for the creation of complex geometries and intricate details while maintaining tight tolerances and superior surface finishes. The process begins with the creation of detailed molds based on precise specifications, followed by the careful pouring of molten materials. Once solidified, these cast components undergo sophisticated machining operations using state-of-the-art CNC equipment to achieve final dimensions and specifications. This dual-process methodology is particularly valuable in industries requiring components with both complex internal geometries and precise external features. The technology enables manufacturers to produce parts with exceptional dimensional accuracy, often achieving tolerances as tight as ±0.005 inches. Modern precision casting and machining operations incorporate advanced quality control systems, including 3D scanning and CMM verification, ensuring consistency across production runs. This manufacturing approach finds extensive applications in aerospace, automotive, medical devices, and industrial equipment sectors, where component reliability and accuracy are paramount.