rapid investment casting

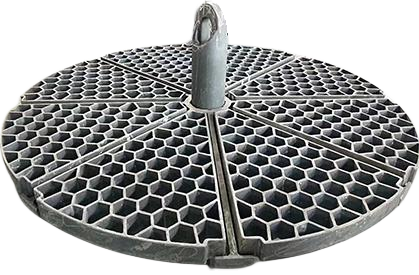

Rapid investment casting represents a revolutionary advancement in traditional investment casting technology, combining the precision of conventional methods with modern rapid prototyping capabilities. This innovative process begins with the creation of a pattern using 3D printing or additive manufacturing technologies, significantly reducing the time and cost associated with traditional pattern making. The process maintains the high accuracy and surface finish characteristic of investment casting while dramatically shortening the product development cycle. During the procedure, a 3D printed pattern is coated with ceramic material to create a shell, which is then heated to remove the pattern and create a cavity. Molten metal is poured into this cavity, producing complex components with exceptional dimensional accuracy and surface quality. This technology proves particularly valuable in industries requiring quick turnaround times for prototypes or small production runs of complex metal parts. The process accommodates a wide range of metals and alloys, making it suitable for aerospace, automotive, medical, and industrial applications. Its ability to produce parts with intricate geometries, thin walls, and fine details while maintaining tight tolerances has made it an indispensable tool in modern manufacturing.