steel casting factory

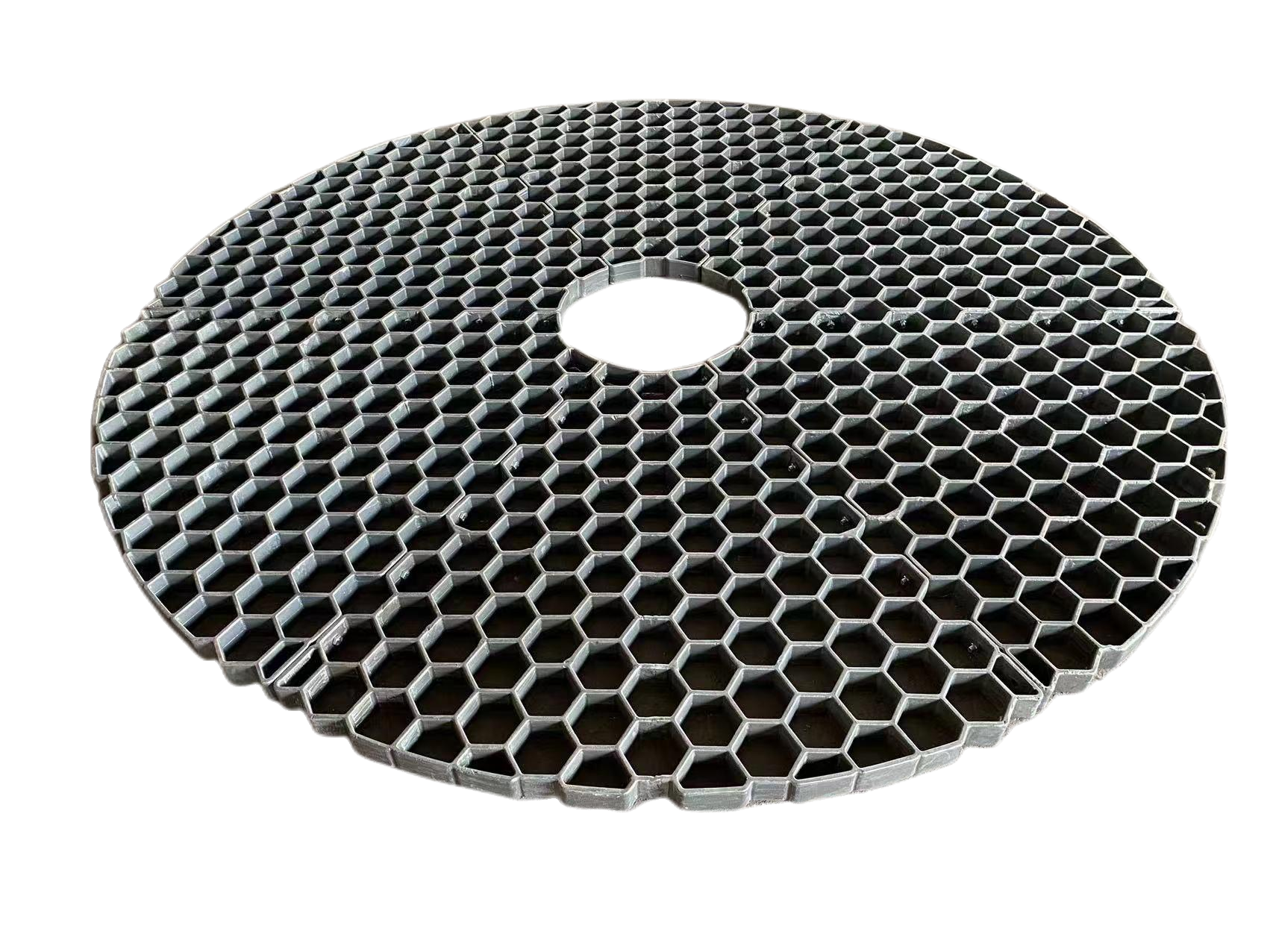

A steel casting factory represents a sophisticated industrial facility dedicated to producing high-quality steel components through various casting processes. The facility incorporates state-of-the-art equipment including electric arc furnaces, induction furnaces, and advanced molding systems that ensure precise temperature control and optimal metallurgical properties. These factories utilize cutting-edge technologies for pattern making, core production, and quality control measures such as X-ray testing and ultrasonic inspection. The manufacturing process begins with careful material selection, followed by melting, molding, and heat treatment stages, all monitored by experienced metallurgists and quality control specialists. The factory's capabilities extend to producing both small precision parts and large industrial components, ranging from a few pounds to several tons. Modern steel casting facilities also implement automated systems for material handling, environmental control measures for dust and emissions management, and advanced cooling systems for efficient production cycles. The factory serves diverse industries including automotive, aerospace, mining, construction, and energy sectors, providing custom solutions for complex engineering requirements.