vakuum-befektetéses öntés

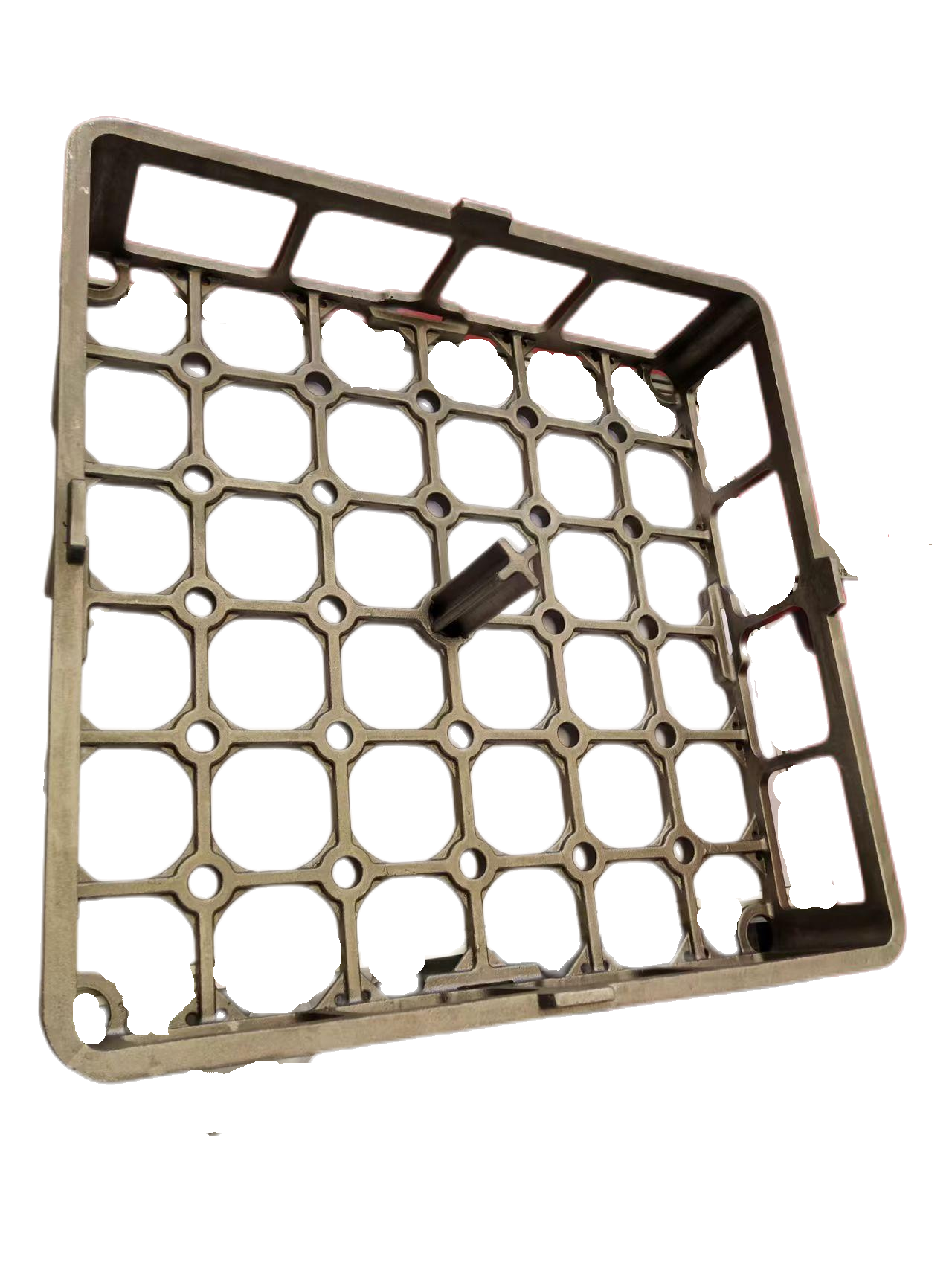

A vakuumos befúrás egy fejlett gyártási folyamat, amely a hagyományos befúrási technikák és a vakuum technológia kombinációját használja a magas pontosságú félmegoldékok előállítására. Ez a bonyolult módszer egy rácsos minta készítését tartalmazza a kívánt részről, majd ceruzamateriállal fedezve formál egy kéreget, és utána kihűtik a rácsot, hogy helyet adjanak a fürdőző félnak. A folyamat jellemzője, hogy vakuum környezetben történik az öntés és a szilárdulás, ami jelentősen növeli a végtermék minőségét. A vakuum feltétele hatékonyan megakadályozza a levegő buborékokat és csökkenti az oxidációt, így jobb felületi megszíntést és mechanikai tulajdonságokat eredményez. Ez a technológia különösen értékes olyan iparágokban, amelyek bonyolult geometriákat és szoros toleranciákat igényelnek, például a repülészeti, orvosi eszközök és a nagy teljesítményű autókomponensek területén. A folyamat lehetővé teszi a bonyolult részek gyártását belső áramútakkal, vékony falakkal és pontos méretekkel, amelyeket nehéz vagy lehetetlen lenne elérni a konvencionális gyártási módszerekkel. Emellett a vakuumos befúrás széles körű fémeket és ligaturákat alkalmazhat, beleértve a superligaturákat, a rostmentes acélot és a titanot, ami egy versengő megoldást tesz lehetővé a követelményes alkalmazásokhoz.