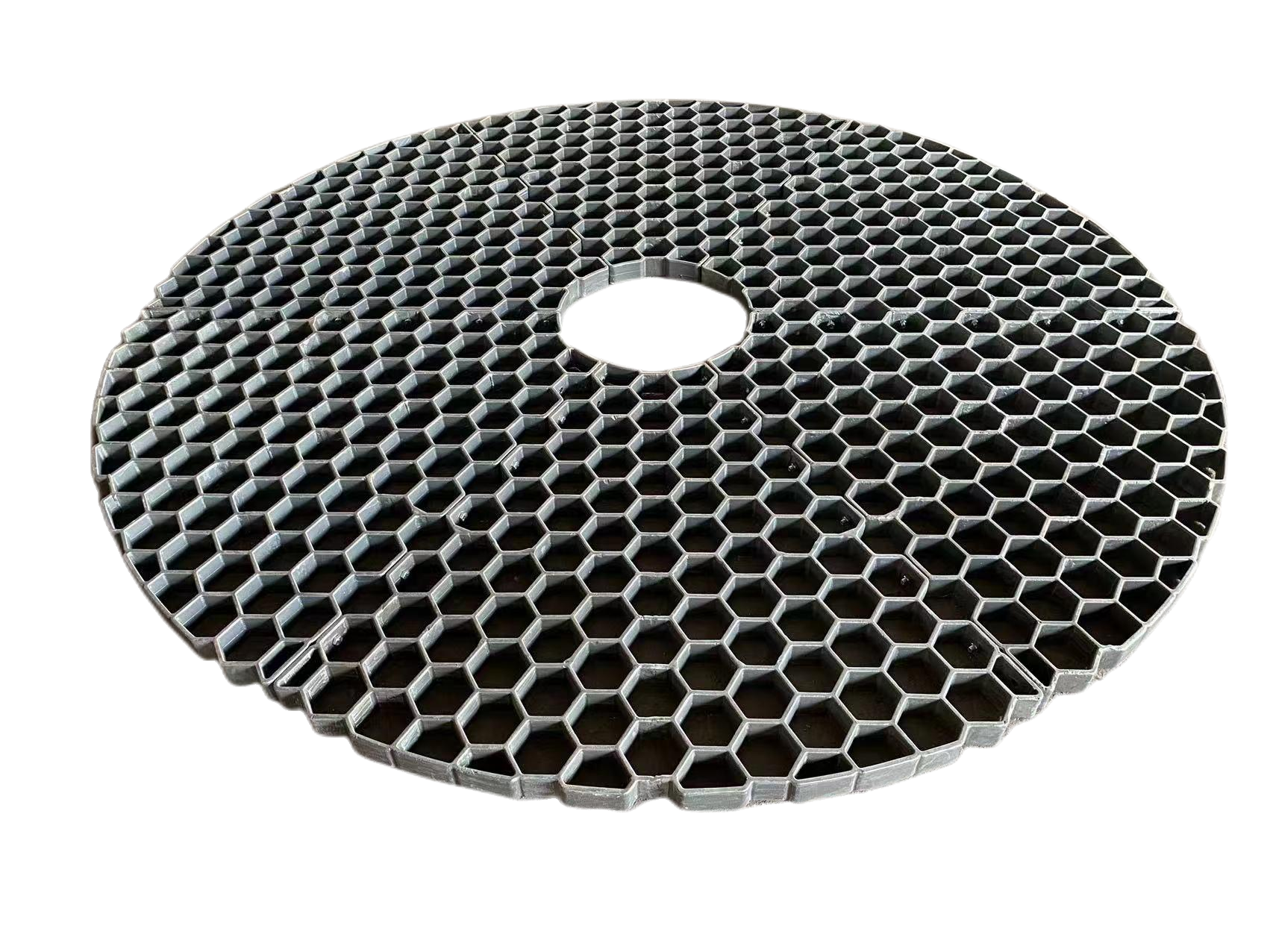

heat resistant steel tray for heat treatment

Heat resistant steel trays for heat treatment are essential industrial components designed to withstand extreme temperatures while maintaining structural integrity. These specialized trays are manufactured using high-grade alloy steel that demonstrates exceptional thermal resistance and durability. The trays feature optimized designs with reinforced structures to prevent warping and deformation under intense heat conditions, typically ranging from 800°C to 1200°C. They serve as crucial equipment in various heat treatment processes, including annealing, tempering, and quenching operations. The construction incorporates advanced metallurgical principles to ensure uniform heat distribution across the tray surface, preventing hot spots and ensuring consistent treatment of materials. These trays often feature special surface treatments that minimize scale formation and extend service life. Their robust construction allows for heavy load bearing capacity while maintaining dimensional stability at elevated temperatures. The trays are engineered with specific attention to thermal expansion characteristics, incorporating design elements that accommodate material movement without compromising structural integrity. They play a vital role in industrial heat treatment processes by providing a stable platform for components undergoing thermal processing while ensuring optimal heat transfer and temperature uniformity.