El Impacto del Diseño del Piso del Horno en la Eficiencia del Tratamiento Térmico

La eficiencia de las operaciones industriales tratamiento térmico operación está profundamente influenciada por el diseño de los pisos de los hornos. Un piso de horno bien diseñado asegura una distribución uniforme del calor, un uso óptimo de la energía y una calidad consistente en los materiales tratados. Al centrarse en los detalles de la construcción del piso, incluyendo la selección de materiales, la disposición y las propiedades térmicas, los fabricantes pueden lograr una mayor productividad y reducir los costos operativos. Los pisos de los hornos actúan como la base para los procesos de tratamiento térmico, y su diseño afecta directamente la uniformidad de temperatura, la flexibilidad de carga y la durabilidad general del equipo. Un diseño cuidadoso del piso puede transformar un horno estándar tratamiento térmico en un componente altamente eficiente y confiable de producción.

Selección de Materiales para Pisso de Hornos

Tipos de Materiales Refractarios

La elección de materiales refractarios desempeña un papel fundamental en el rendimiento del suelo del horno. Ladrillos de alta calidad, refractarios moldeables y baldosas cerámicas ofrecen una excelente resistencia térmica y durabilidad. Cada material tiene ventajas específicas para soportar la expansión térmica, la exposición química y el estrés mecánico. Una selección adecuada garantiza que el suelo del horno mantenga su integridad incluso bajo ciclos prolongados de tratamiento térmico.

Consideraciones de Conductividad Térmica

La conductividad térmica de los materiales del suelo afecta la forma en que el calor se distribuye por todo el horno. Los materiales con conductividad uniforme ayudan a alcanzar temperaturas constantes en toda la carga, evitando puntos calientes y tratamientos irregulares. Los diseñadores deben equilibrar una alta retención de calor con una transferencia controlada de energía para optimizar la eficiencia del tratamiento térmico.

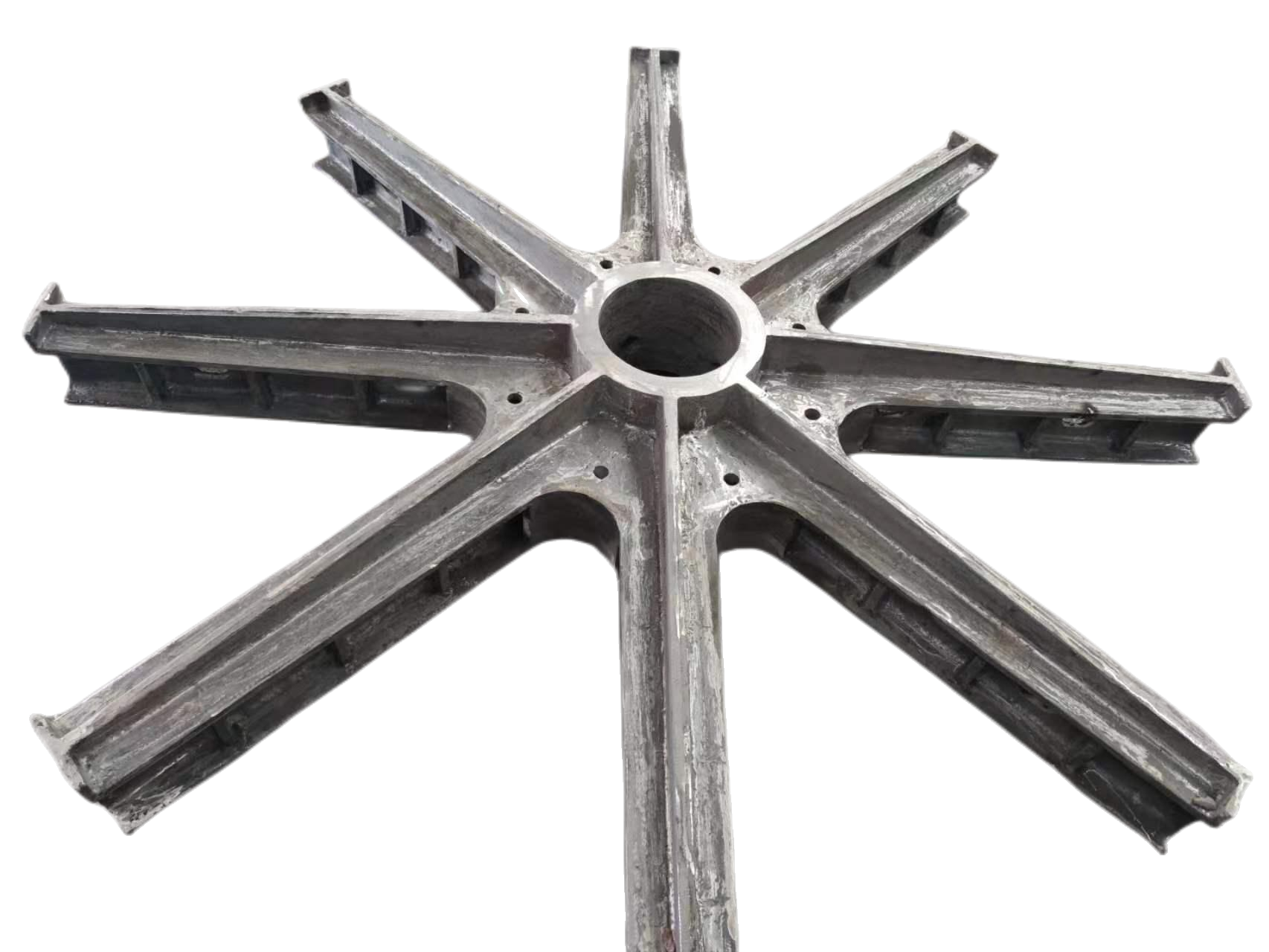

Distribución y Diseño Estructural

Espesor y Soporte del Suelo

El grosor del suelo del horno debe soportar el peso de cargas pesadas sin deformarse. Un soporte estructural adecuado evita la deformación con el tiempo, lo cual podría provocar un tratamiento térmico irregular y daños en el equipo. Refuerzos como estructuras de acero o capas distribuidoras de carga suelen incorporarse en el diseño.

Disposición de la Carga y Accesibilidad

Una disposición adecuada permite la colocación flexible de piezas durante el tratamiento térmico. Un espaciado optimizado favorece la circulación del aire y un calentamiento uniforme, mientras que una fácil accesibilidad facilita la carga y descarga, reduciendo tiempos muertos. La disposición también minimiza los gradientes térmicos que pueden afectar negativamente a la calidad del producto.

Flujo y Distribución del Calor

Dinámica de Convección y Radiación

La eficiencia del tratamiento térmico depende de cómo se transfiere el calor desde el suelo del horno hasta las piezas a tratar. Las corrientes de convección y la distribución del calor radiante deben gestionarse cuidadosamente. El diseño del suelo puede incluir canales o superficies que mejoren el flujo de aire, asegurando que cada pieza reciba una exposición térmica consistente.

Evitar puntos calientes y fríos

El calentamiento desigual provoca puntos calientes y fríos que comprometen el proceso de tratamiento térmico. La colocación estratégica de materiales refractarios, capas de aislamiento y estructuras de soporte ayuda a mantener temperaturas uniformes. El monitoreo regular y los ajustes en el suelo mejoran aún más la fiabilidad.

Mantenimiento y longevidad

Resistencia al desgaste y a la abrasión

Los suelos de los hornos soportan temperaturas extremas y desgaste mecánico causado por las operaciones de carga y descarga. Materiales duraderos y recubrimientos protectores reducen la abrasión, prolongando la vida útil del suelo y minimizando los costos de reparación. La eficiencia del tratamiento térmico se mantiene alta cuando la superficie del suelo permanece intacta y nivelada.

Técnicas de Reparación

Daños menores, como grietas o desprendimientos, pueden afectar la transferencia de calor. Reparar a tiempo utilizando materiales refractarios compatibles previene interrupciones en el proceso. Los programas de mantenimiento preventivo aseguran que el piso del horno continúe apoyando operaciones eficientes de tratamiento térmico.

Consideraciones sobre la eficiencia energética

Aislamiento y retención de calor

Los pisos de horno adecuadamente aislados reducen la pérdida de calor, disminuyendo el consumo de combustible y los costos operativos. Las capas de aislamiento debajo del piso actúan como barreras, reteniendo el calor donde es necesario para el proceso de tratamiento térmico. Una gestión térmica eficiente contribuye directamente al ahorro energético.

Optimización del uso de la energía

El diseño del piso del horno puede mejorar la eficiencia energética general al minimizar el tiempo requerido para alcanzar las temperaturas objetivo. Una distribución uniforme del calor reduce la necesidad de aportar energía en exceso, mientras que termopares y sensores estratégicamente colocados permiten un control preciso de la temperatura.

Técnicas Avanzadas de Diseño de Pisos

Paneles Modulares y Reemplazables

El uso de paneles modulares para los suelos de hornos ofrece flexibilidad en el mantenimiento y los ajustes de configuración. Las secciones dañadas pueden reemplazarse individualmente sin apagar todo el horno, asegurando operaciones continuas de tratamiento térmico.

Perfiles Térmicos Personalizados

Los diseños avanzados de suelos de hornos pueden soportar perfiles térmicos personalizados. Mediante el control de la masa térmica y la geometría de la superficie, se pueden optimizar zonas específicas del suelo para diferentes ciclos de tratamiento térmico, mejorando tanto la calidad del producto como la eficiencia del proceso.

Impacto en la Calidad del Producto

Consistencia en el Tratamiento Térmico

Los suelos uniformes en el horno conducen a una exposición térmica consistente, lo cual afecta directamente a la microestructura y propiedades mecánicas del producto. Un diseño confiable del suelo reduce la probabilidad de defectos y mejora la repetibilidad de los ciclos de tratamiento térmico.

Minimización de Tensiones Residuales

El flujo adecuado de calor desde el suelo del horno ayuda a reducir las tensiones residuales en los componentes tratados. Esto es crucial para materiales como metales y aleaciones, donde la concentración de tensión puede provocar deformaciones, grietas o problemas de rendimiento.

Seguridad y fiabilidad operativa

Estabilidad y seguridad del suelo

Un suelo bien construido en el horno asegura estabilidad, evitando accidentes durante las operaciones de carga y descarga. Los suelos estables también reducen las vibraciones, contribuyendo a un manejo más seguro de artículos delicados o pesados durante el tratamiento térmico.

Reducción del tiempo de inactividad

El diseño de alta calidad del suelo minimiza la necesidad de reparaciones e interrupciones para mantenimiento. El rendimiento constante permite planificar la producción de manera predecible, aumentando la fiabilidad operativa y la eficiencia general en plantas de tratamiento térmico.

Innovación en el diseño del suelo del horno

Integración con Automatización

Las operaciones modernas de tratamiento térmico suelen integrar sistemas de automatización para la carga, el monitoreo de temperatura y el control de ciclos. Los pisos de los hornos pueden diseñarse para acomodar equipos de manipulación robóticos, mejorando la precisión y reduciendo los requisitos de mano de obra.

Prácticas de Diseño Sostenible

Los materiales sostenibles y los diseños de piso eficientes en el uso de energía contribuyen a procesos de tratamiento térmico más ecológicos. El uso de componentes refractarios reciclados o configuraciones de piso que retienen energía reduce el impacto ambiental manteniendo la efectividad del proceso.

Preguntas frecuentes

¿Cuál es el papel de los pisos de los hornos en el tratamiento térmico?

Los pisos de los hornos proporcionan la base para los procesos de tratamiento térmico. Aseguran una distribución uniforme del calor, soportan cargas pesadas y contribuyen a la eficiencia energética, afectando directamente la calidad del producto y la confiabilidad operativa.

¿Cómo afecta el material del piso a la eficiencia del tratamiento térmico?

La selección de materiales afecta la conductividad térmica, la durabilidad y la resistencia al estrés térmico. Los materiales óptimos ayudan a mantener temperaturas uniformes y reducir puntos fríos o calientes, mejorando la eficiencia general del proceso.

¿Se pueden personalizar las soleras de los hornos para diferentes ciclos de tratamiento térmico?

Sí, los diseños avanzados permiten perfiles térmicos personalizados y configuraciones modulares. Esta personalización posibilita un control preciso de las zonas de calentamiento y acomoda distintos tipos de productos, mejorando la eficiencia y la consistencia.

¿Qué mantenimiento requieren las soleras de los hornos?

Las inspecciones regulares, la limpieza y reparaciones menores, como rellenar grietas o reemplazar secciones desgastadas, son esenciales. El mantenimiento preventivo asegura un desempeño estable, minimiza el tiempo de inactividad y preserva la eficiencia del tratamiento térmico.

Tabla de Contenido

- El Impacto del Diseño del Piso del Horno en la Eficiencia del Tratamiento Térmico

- Selección de Materiales para Pisso de Hornos

- Distribución y Diseño Estructural

- Flujo y Distribución del Calor

- Mantenimiento y longevidad

- Consideraciones sobre la eficiencia energética

- Técnicas Avanzadas de Diseño de Pisos

- Impacto en la Calidad del Producto

- Seguridad y fiabilidad operativa

- Innovación en el diseño del suelo del horno

- Preguntas frecuentes