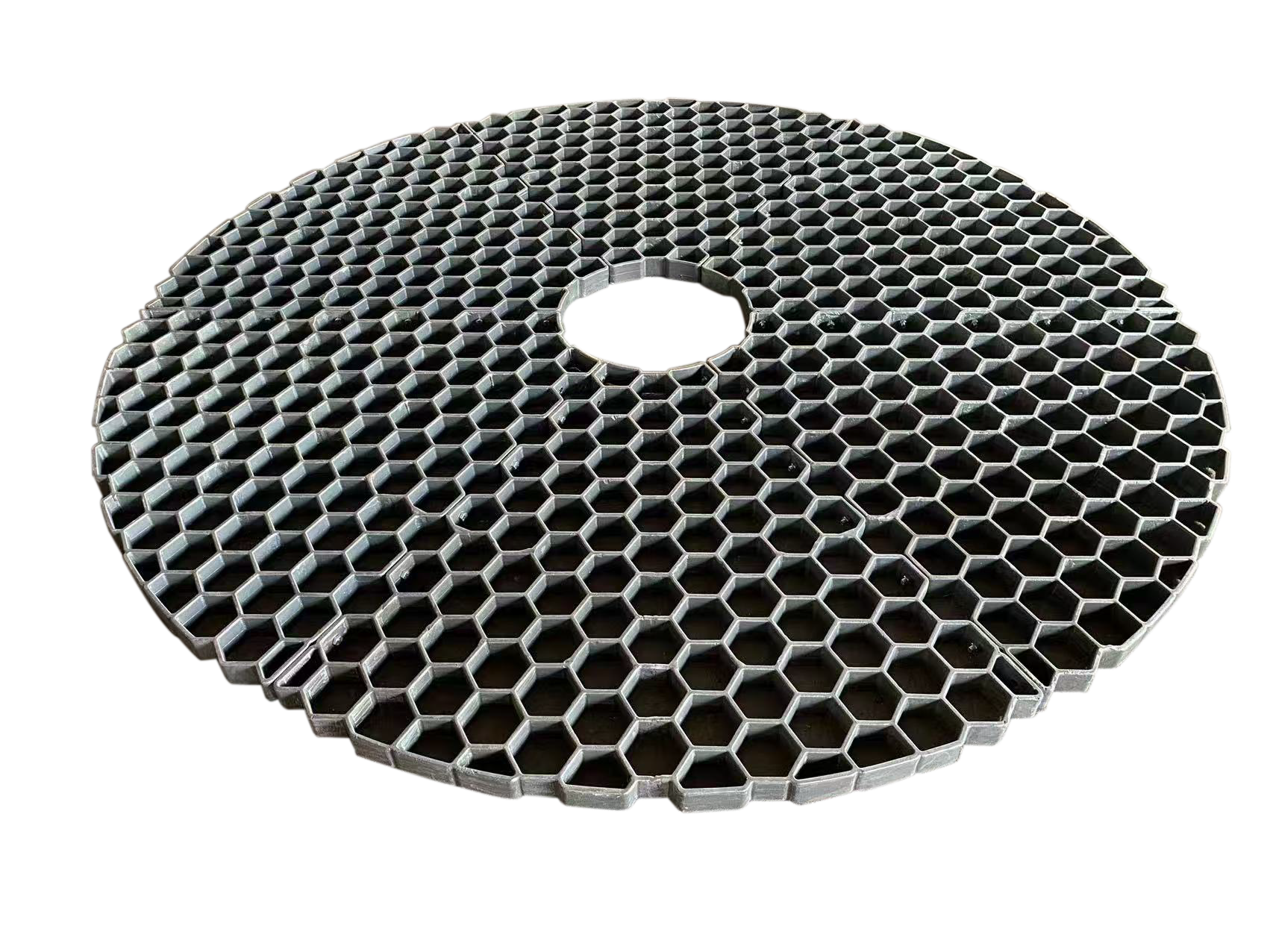

casting and machining services

Casting and machining services represent a comprehensive manufacturing solution that combines traditional foundry techniques with advanced precision engineering. These integrated services encompass the entire production process, from initial mold design to final component finishing. The casting process begins with creating detailed molds based on customer specifications, utilizing various materials including steel, aluminum, brass, and iron. Advanced computer-aided design (CAD) systems ensure precise mold creation, while quality control measures maintain consistency throughout the casting process. The machining phase employs state-of-the-art CNC equipment to achieve exceptional accuracy in dimensional specifications, surface finishing, and complex geometrical features. This dual-capability service enables the production of both simple and intricate components, suitable for industries ranging from automotive and aerospace to medical equipment manufacturing. The integration of casting and machining services streamlines production timelines, reduces costs, and ensures superior quality control throughout the manufacturing process. Modern facilities equipped with advanced metrology tools guarantee that final products meet exact specifications and industry standards.