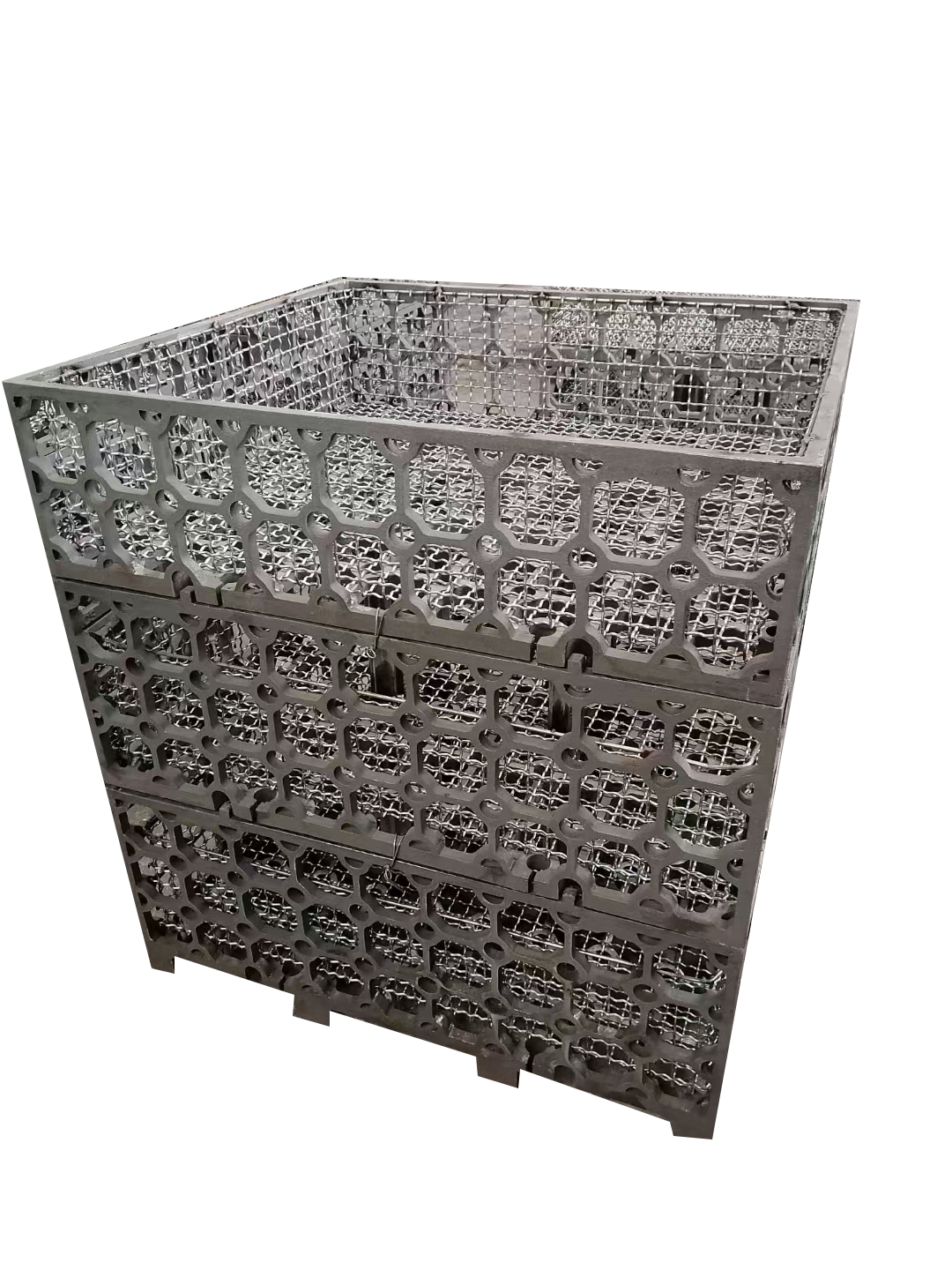

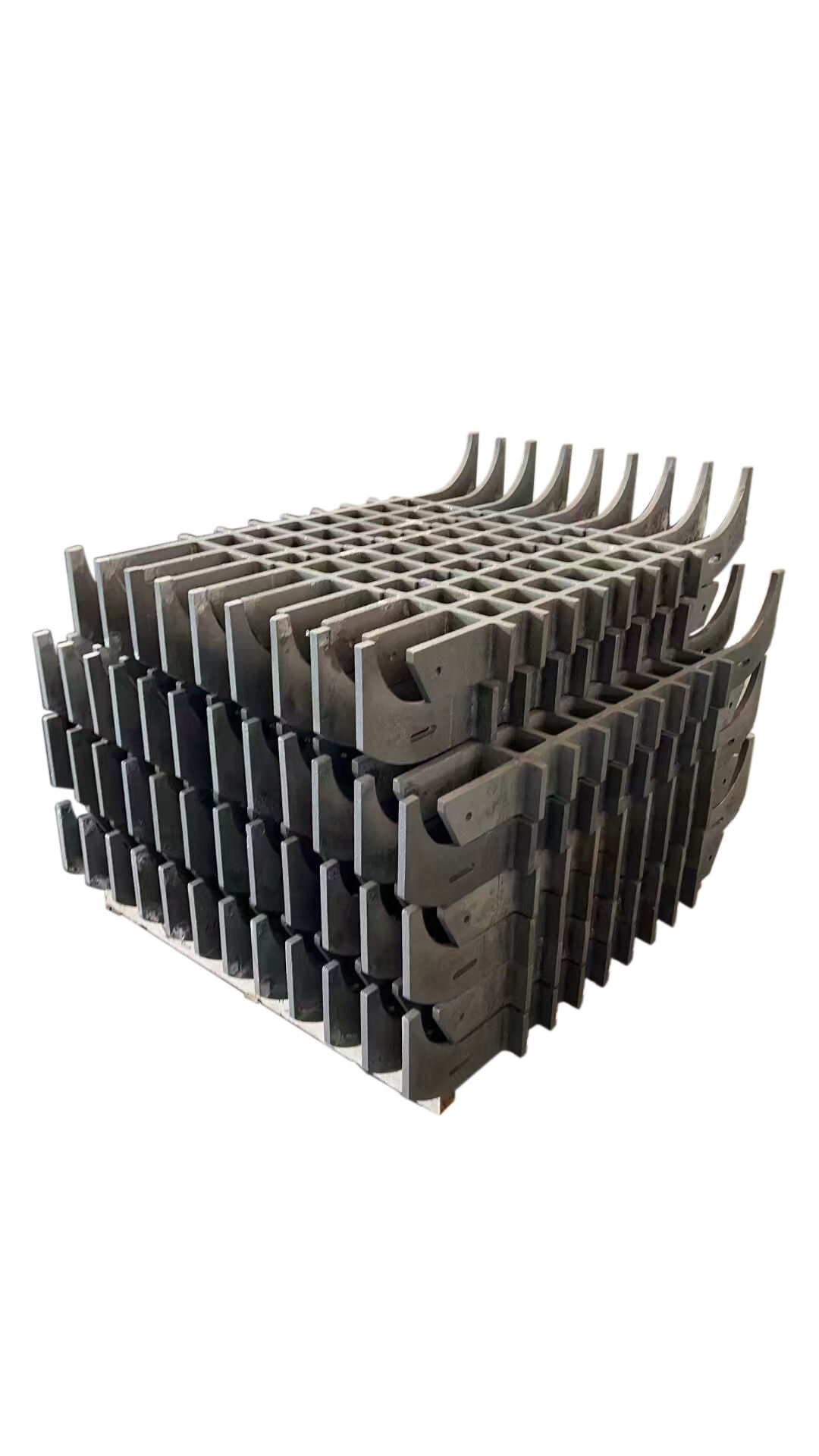

custom metal casting

Custom metal casting is a sophisticated manufacturing process that transforms molten metal into precisely engineered components according to specific design requirements. This versatile technique combines traditional foundry methods with modern technology to create complex metal parts that would be difficult or impossible to produce through other manufacturing methods. The process begins with the creation of a detailed pattern, followed by mold making, metal melting, pouring, and finishing operations. Custom metal casting supports a wide range of materials, including aluminum, steel, bronze, and iron, each chosen based on the intended application's requirements. The technology enables manufacturers to produce components with intricate geometries, internal cavities, and varying wall thicknesses while maintaining consistent quality. This method is particularly valuable in industries requiring specialized parts, such as automotive, aerospace, machinery manufacturing, and architectural applications. Advanced computer-aided design (CAD) and simulation tools ensure optimal results by allowing engineers to analyze and refine designs before production begins. The process also accommodates various production volumes, from single prototypes to large production runs, making it adaptable to diverse manufacturing needs.