investment casting company

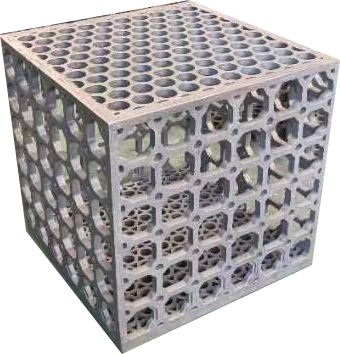

Investment casting companies represent the pinnacle of precision manufacturing, offering a sophisticated metal forming process that delivers exceptional quality and complexity in finished parts. These companies utilize advanced technologies to create intricate components through a meticulous lost-wax casting process. Starting with precise pattern creation, skilled technicians develop wax models that are carefully coated with ceramic material to form robust molds. The process employs state-of-the-art equipment for wax removal, mold firing, and metal pouring, ensuring consistent quality across production runs. Modern investment casting facilities maintain strict quality control measures, implementing advanced inspection technologies and maintaining ISO certifications to meet rigorous industry standards. These companies serve diverse sectors including aerospace, medical devices, automotive, and industrial equipment manufacturing, producing components that range from turbine blades to surgical instruments. Their capabilities extend to working with various metals and alloys, including stainless steel, aluminum, titanium, and superalloys, offering customers flexibility in material selection. Advanced simulation software and rapid prototyping technologies enable these companies to optimize designs and reduce development cycles, providing cost-effective solutions for complex manufacturing challenges.