vacuum casting services

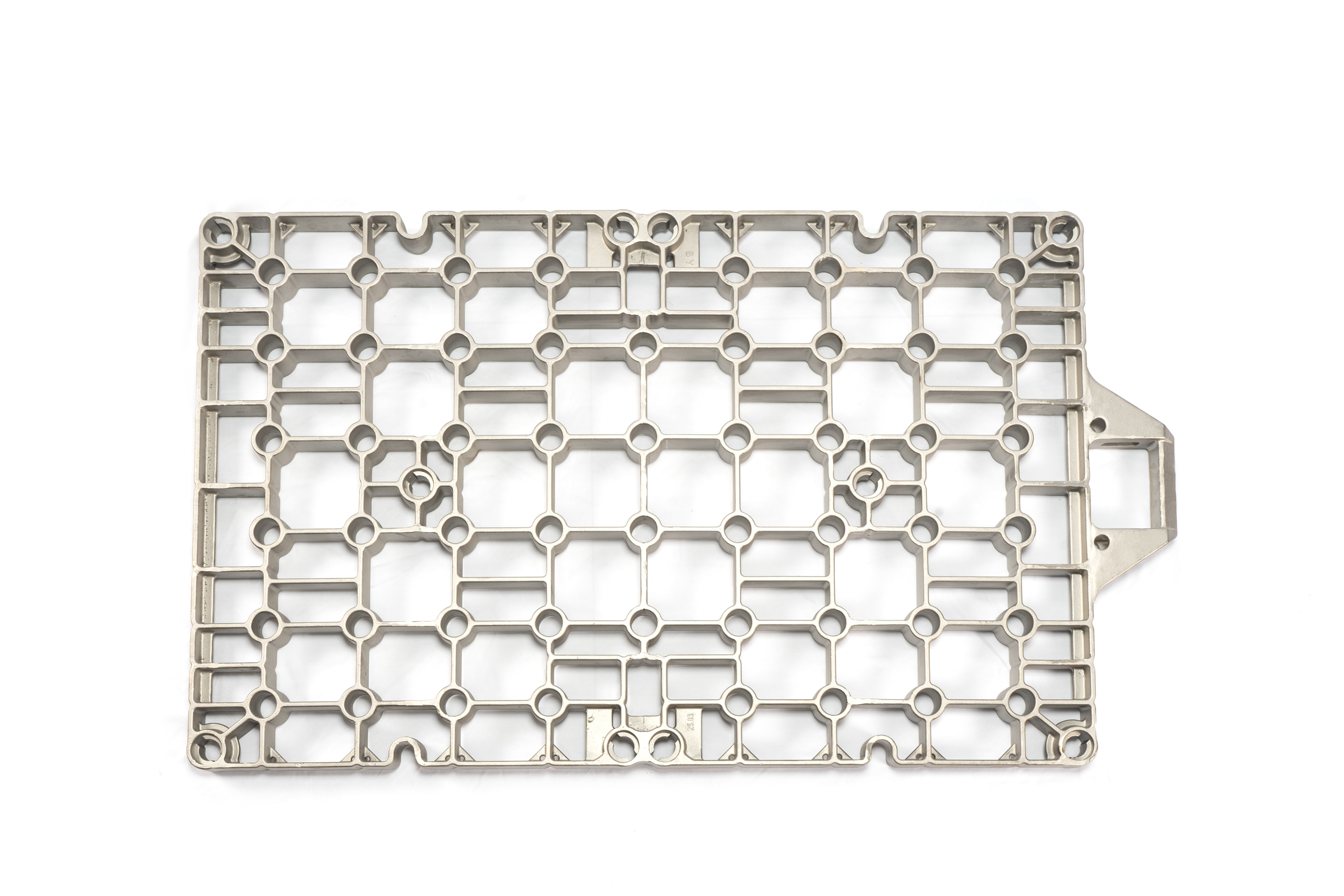

Vacuum casting services represent a sophisticated manufacturing process that combines precision engineering with cost-effective production solutions. This advanced technology utilizes silicone molds to create high-quality replicas of master patterns under controlled vacuum conditions. The process begins with the creation of a master pattern, followed by the development of a silicone mold, which can then produce multiple copies with exceptional detail and accuracy. The vacuum environment eliminates air bubbles and ensures complete material flow, resulting in products with superior surface finish and structural integrity. This service is particularly valuable for prototyping, small-batch production, and creating complex geometries that would be challenging with traditional manufacturing methods. The technology accommodates a wide range of materials, including polyurethane resins, which can simulate various engineering plastics. The service is especially beneficial for industries requiring rapid prototyping, product development, and functional testing. With capabilities to produce parts ranging from small components to larger assemblies, vacuum casting services offer flexibility in both size and complexity. The process also allows for the incorporation of different colors and material properties, making it ideal for creating presentation models and functional prototypes that closely resemble final production parts.