investment casting services

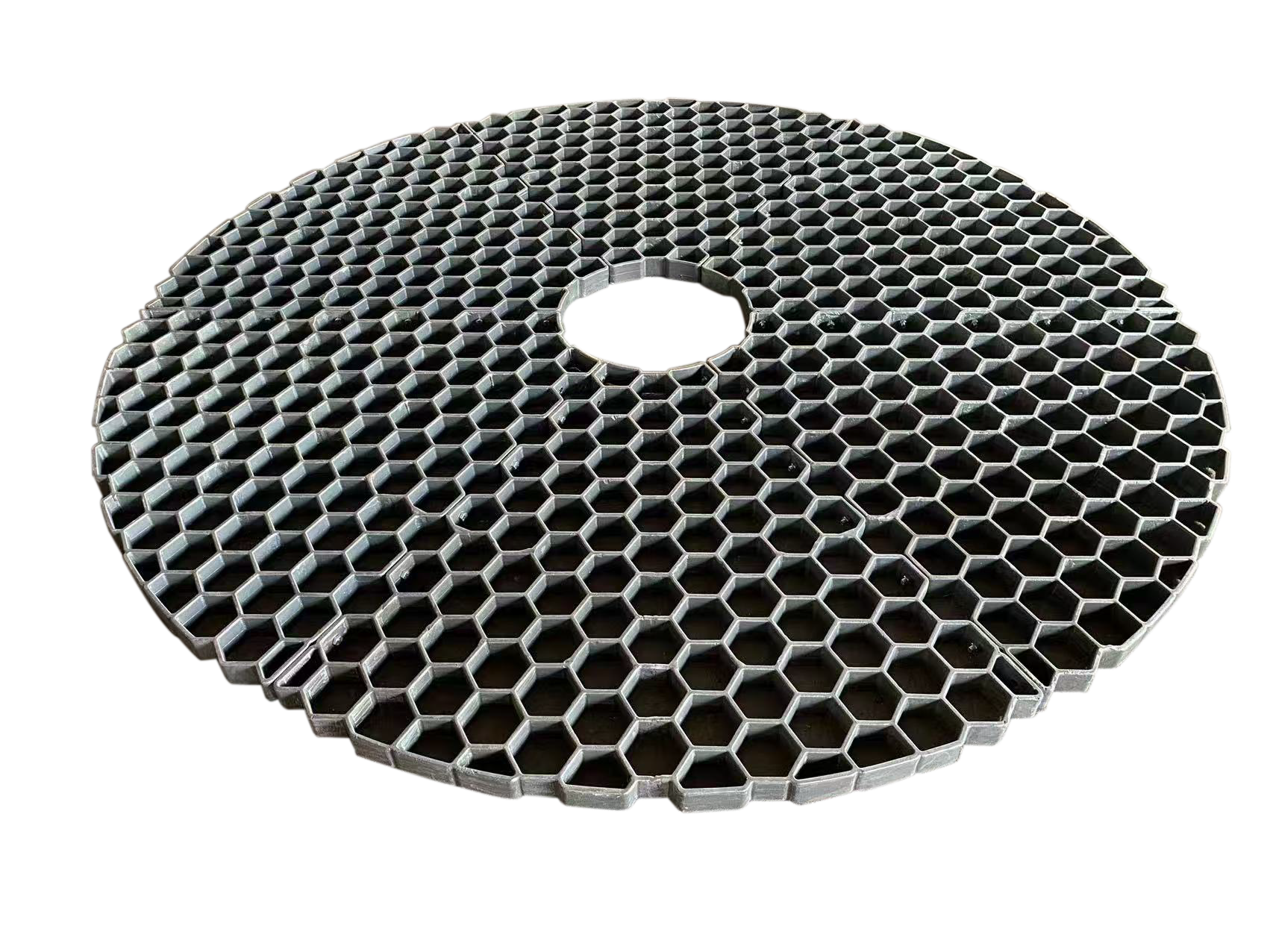

Investment casting services represent a sophisticated manufacturing process that delivers exceptional precision and versatility in producing complex metal components. This ancient technique, modernized for contemporary industrial applications, begins with creating a wax pattern that precisely mirrors the desired final product. The pattern is coated with ceramic material to form a rigid shell, after which the wax is melted away, leaving a perfect cavity for molten metal. This process enables the production of intricate parts with excellent surface finish, tight tolerances, and complex geometries that would be difficult or impossible to achieve through other manufacturing methods. Investment casting services cater to diverse industries, including aerospace, automotive, medical devices, and industrial equipment manufacturing. The process allows for the use of a wide range of metals and alloys, from standard steels to exotic materials like titanium and superalloys. Modern investment casting facilities employ advanced technology for pattern creation, shell building, and quality control, ensuring consistent production of high-quality components. This method is particularly valuable for projects requiring detailed features, internal cavities, and precise dimensional accuracy, making it an ideal choice for both prototype development and high-volume production runs.