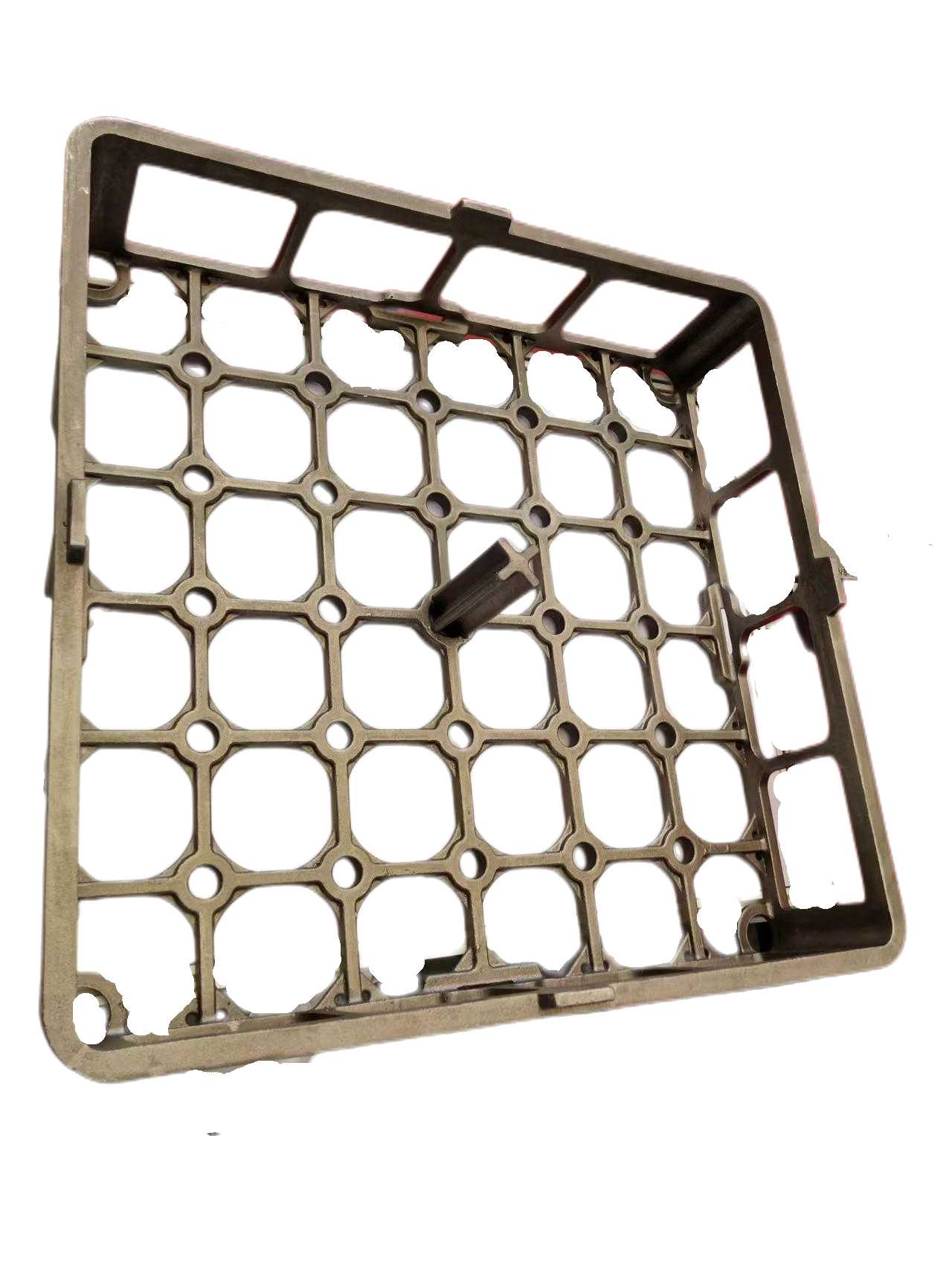

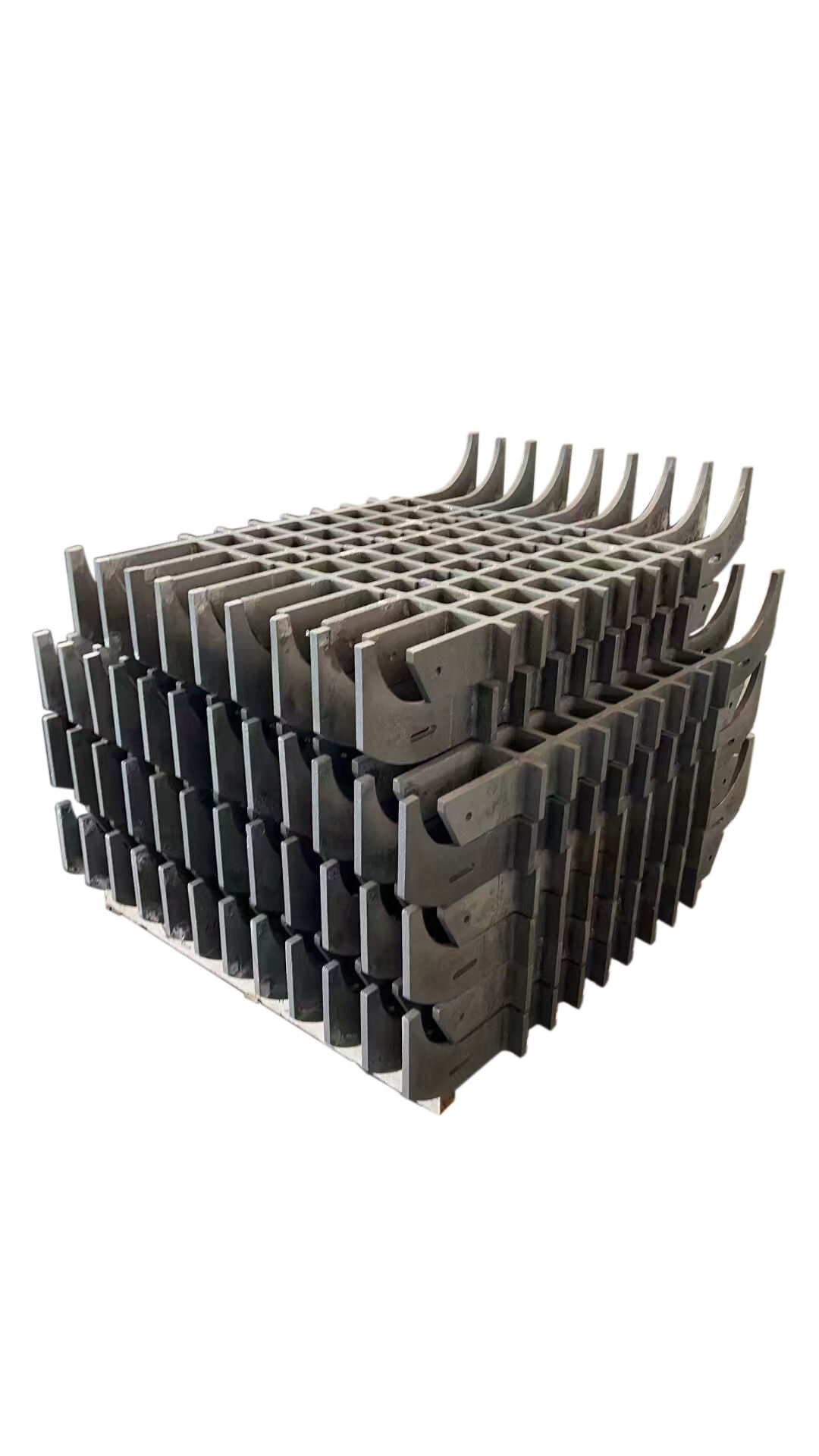

high manganese steel casting

High manganese steel casting represents a groundbreaking advancement in metallurgical engineering, characterized by its exceptional combination of hardness and toughness. This innovative material, containing 11-14% manganese and 1.0-1.4% carbon, undergoes a unique transformation during service, where its surface work-hardens through impact and pressure while maintaining a tough core. The casting process involves precise temperature control and specialized cooling techniques to achieve optimal mechanical properties. These castings excel in applications requiring high wear resistance and impact strength, making them indispensable in mining equipment, crusher components, and railway track work. The material's ability to withstand extreme conditions while maintaining structural integrity has revolutionized industrial applications. Modern manufacturing techniques have enhanced the consistency and quality of high manganese steel castings, ensuring reliable performance in demanding environments. The unique work-hardening characteristic allows the material to develop surface hardness up to 500 Brinell, while the interior remains ductile and tough, providing an ideal combination for heavy-duty applications.