steel alloys & services

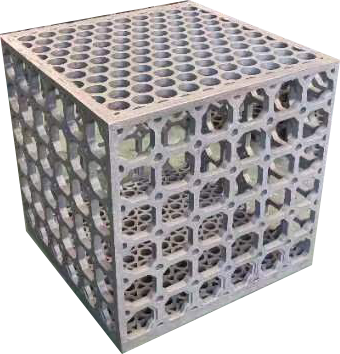

Steel alloys and services represent a comprehensive solution in modern metallurgy, combining advanced material science with specialized industrial services. These alloys are engineered combinations of iron with various elements like chromium, nickel, and molybdenum, creating materials with enhanced properties beyond standard steel. The services encompass everything from material selection and heat treatment to quality testing and custom fabrication. Modern steel alloys are designed to meet specific performance requirements, offering exceptional strength-to-weight ratios, corrosion resistance, and durability across diverse applications. They are extensively used in aerospace, automotive manufacturing, construction, and heavy industry. The technology behind these alloys involves precise control of chemical composition and processing parameters, ensuring consistent quality and performance. Advanced testing facilities and expert metallurgists work together to deliver materials that meet or exceed industry standards. Services include detailed material analysis, custom alloying solutions, heat treatment optimization, and comprehensive quality assurance protocols. This integrated approach ensures that clients receive not just high-quality materials but also the technical support and expertise needed to optimize their use in specific applications.