custom stainless steel parts manufacturer

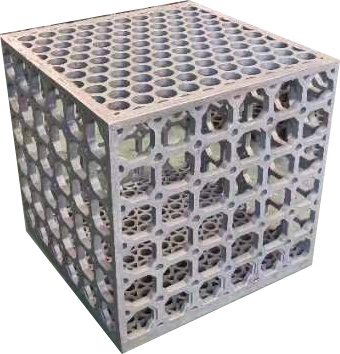

A custom stainless steel parts manufacturer represents a cornerstone in modern industrial manufacturing, offering specialized solutions for diverse applications across multiple sectors. These facilities combine advanced CNC machining technology, precision engineering, and metallurgical expertise to produce high-quality stainless steel components tailored to exact specifications. The manufacturing process encompasses multiple capabilities, including precision cutting, forming, welding, and finishing operations, all conducted under stringent quality control measures. State-of-the-art equipment, including advanced CNC machines, laser cutting systems, and automated welding stations, ensures consistent precision and repeatability in production. The manufacturer's expertise extends to various grades of stainless steel, including 304, 316, and 430, enabling them to meet specific requirements for corrosion resistance, strength, and durability. They serve industries ranging from aerospace and automotive to medical equipment and food processing, providing custom solutions that meet industry-specific standards and regulations. The facility's comprehensive approach includes design assistance, prototyping services, and full-scale production capabilities, supported by experienced engineers and skilled technicians who ensure optimal results for each project.