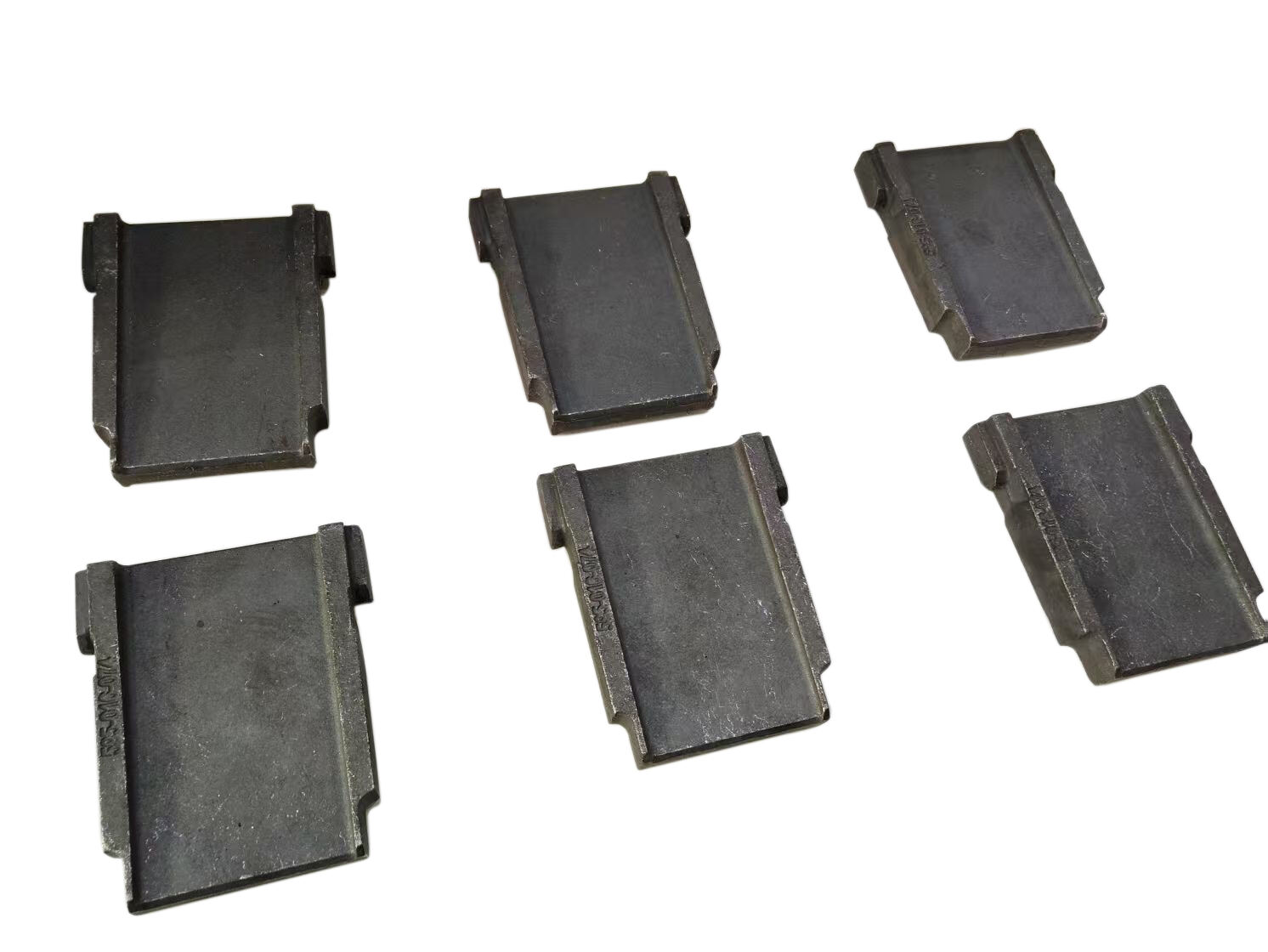

metal investment casting

Metal investment casting, also known as lost-wax casting, is a sophisticated manufacturing process that enables the production of highly complex and precise metal components. This time-tested method begins with creating a wax pattern identical to the desired final product, which is then coated with ceramic material to form a shell. Once the ceramic hardens, the wax is melted and drained away, leaving a perfect negative mold of the component. Molten metal is then poured into this cavity, allowed to solidify, and finally, the ceramic shell is broken away to reveal the finished casting. This process stands out for its ability to produce near-net-shape parts with excellent surface finishes, intricate details, and tight tolerances. The technology accommodates a wide range of metals and alloys, from aluminum and steel to exotic materials like titanium and superalloys. In modern manufacturing, investment casting serves crucial roles in aerospace, medical devices, automotive components, and precision machinery, where complex geometries and high-quality standards are paramount. The process's versatility allows for the creation of both small, delicate components and larger structural parts, making it an invaluable manufacturing solution across various industries.