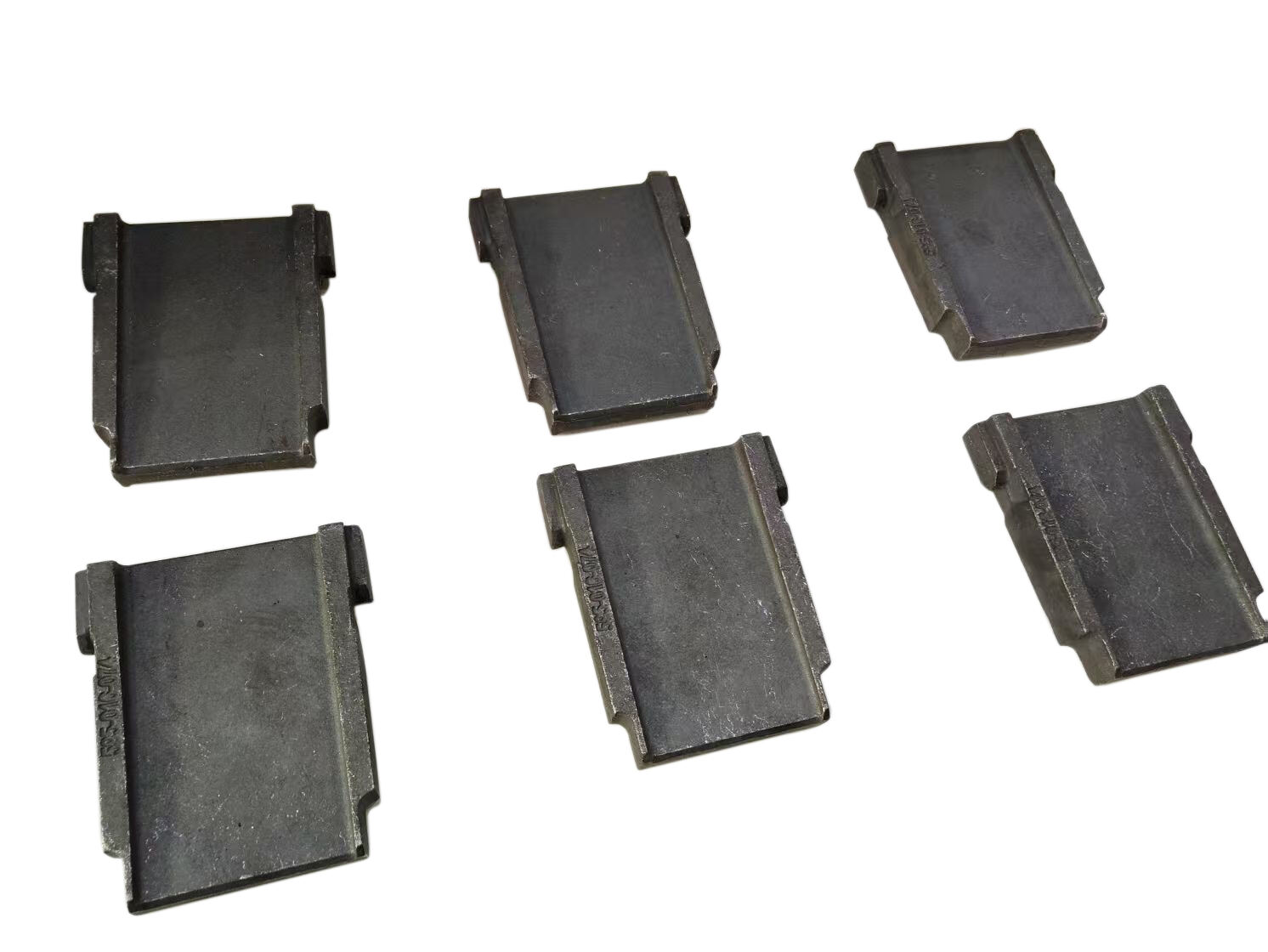

multilayer heat treatment tray

The multilayer heat treatment tray represents a significant advancement in thermal processing equipment, designed to optimize heat treatment operations across various industrial applications. This innovative system features multiple layers of precisely engineered platforms that enable simultaneous processing of numerous components, maximizing operational efficiency and throughput. The tray's construction typically incorporates high-grade heat-resistant materials, ensuring durability and consistent performance under extreme temperature conditions. Each layer is strategically designed with optimal spacing and air circulation channels, facilitating uniform heat distribution and ensuring consistent treatment results across all items. The system's modular design allows for customizable configurations, accommodating different product sizes and shapes while maintaining process integrity. Advanced thermal management features include specialized heat distribution channels and temperature-resistant coating technologies, enabling precise control over heating and cooling cycles. The tray system integrates seamlessly with existing heat treatment equipment, offering enhanced loading capacity without compromising treatment quality. Its robust construction supports various heat treatment processes, including hardening, tempering, annealing, and stress relieving, making it an versatile solution for manufacturing operations.