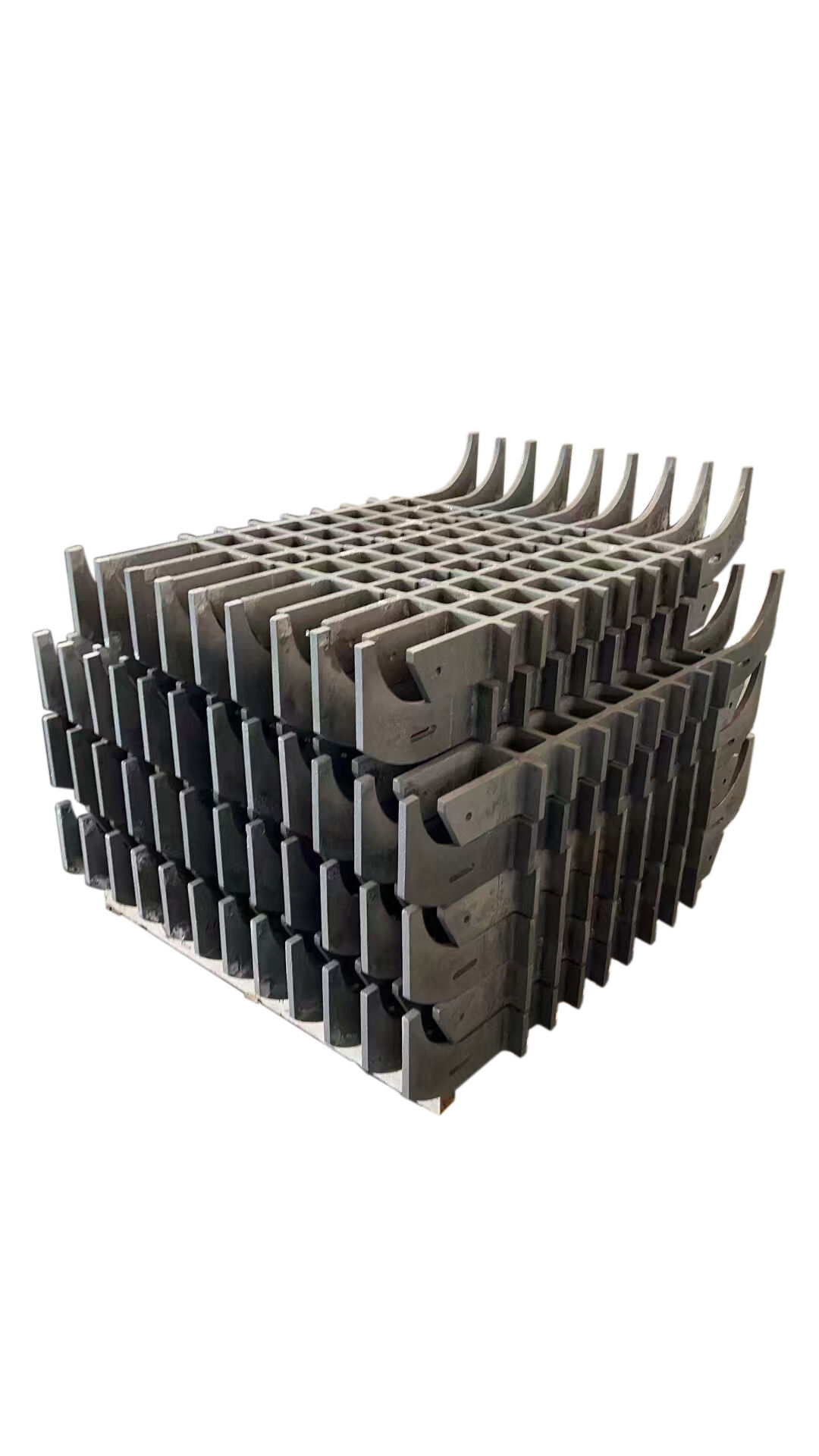

precision investment casting process

Precision investment casting, also known as lost wax casting, is a sophisticated manufacturing process that enables the production of complex metal parts with exceptional accuracy and surface finish. This process begins with creating a wax pattern that precisely mirrors the desired final product. The pattern is then coated with ceramic material to form a shell, which is subsequently heated to melt out the wax, leaving a perfect cavity for metal pouring. The molten metal is poured into this cavity, allowed to solidify, and finally, the ceramic shell is broken away to reveal the finished casting. This method stands out for its ability to produce intricate components with tight tolerances, minimal machining requirements, and excellent dimensional accuracy. The process is particularly valuable in industries requiring high precision components, such as aerospace, medical equipment, and automotive sectors. One of its key technological features is the capability to cast a wide range of metals and alloys, including stainless steel, aluminum, and titanium. The process can accommodate complex geometries, internal passages, and fine details that would be difficult or impossible to achieve with other manufacturing methods. Modern investment casting facilities often employ advanced technologies like 3D printing for pattern making and automated dipping systems for shell building, further enhancing precision and efficiency.