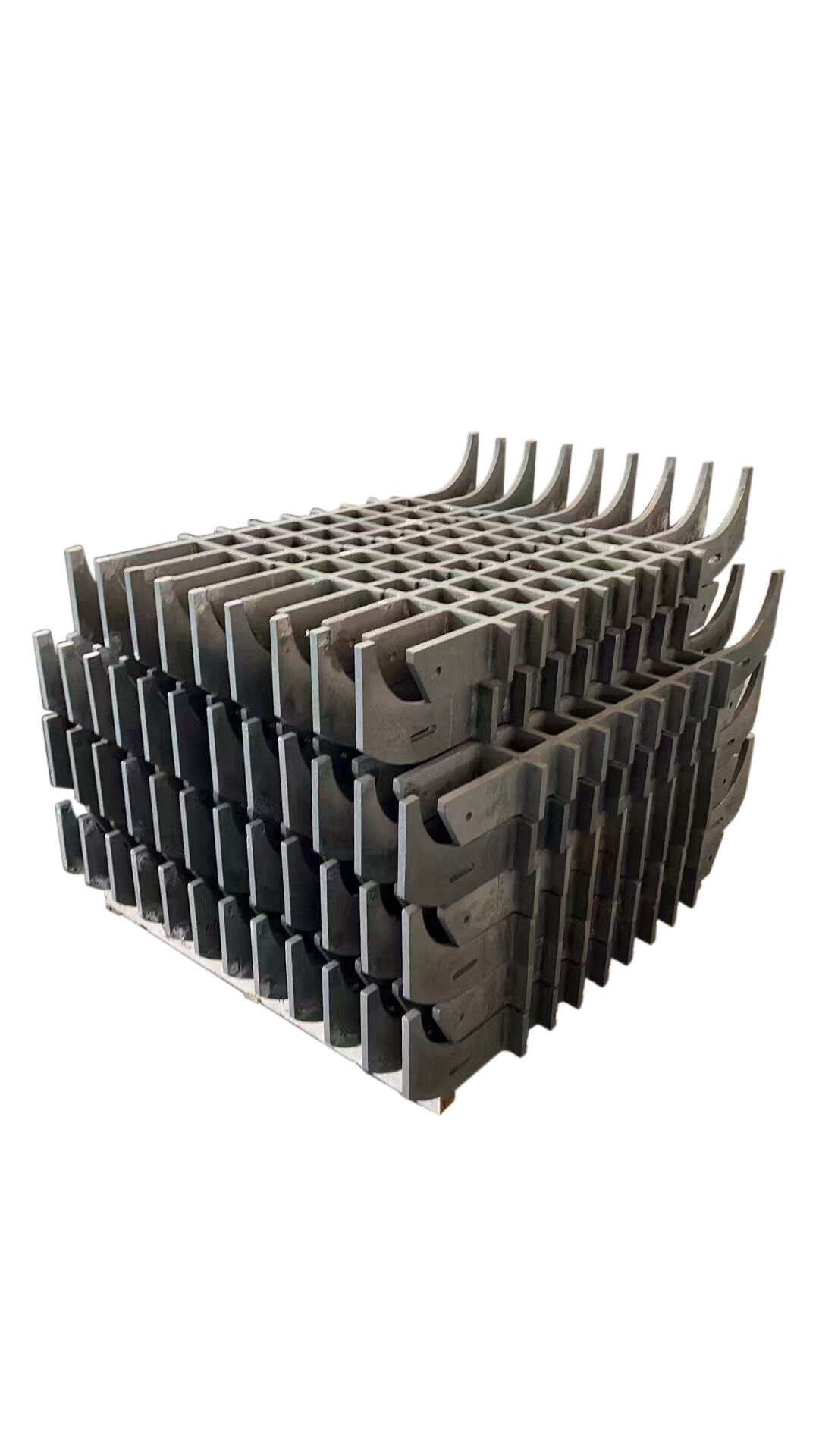

alloy steel investment casting

Alloy steel investment casting represents a sophisticated manufacturing process that combines precision engineering with superior material properties. This method involves creating complex metal components by pouring molten alloy steel into exceptionally accurate molds formed using wax patterns. The process begins with the creation of a wax model of the desired component, followed by the application of ceramic material to form a shell around the pattern. Once the ceramic hardens, the wax is melted out, leaving a precise cavity for the molten alloy steel. This technique enables the production of intricate parts with exceptional surface finish and dimensional accuracy. The process is particularly valuable in industries requiring components with complex geometries, thin walls, and precise specifications. Alloy steel investment casting offers significant advantages in terms of material utilization, reduced machining requirements, and the ability to produce parts that would be difficult or impossible to manufacture using traditional methods. The process is widely employed in aerospace, automotive, medical equipment, and industrial machinery manufacturing, where high-performance components with specific mechanical properties are essential.