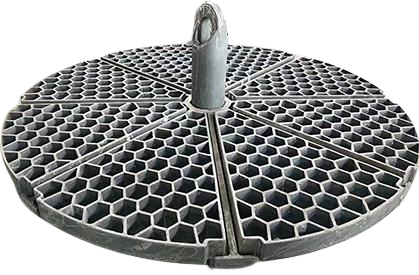

heat treatment basket

A heat treatment basket is an essential industrial apparatus designed for holding and transporting components during various thermal processing operations. These specialized containers are engineered with high-temperature resistant materials, typically featuring a mesh or grid-like construction that enables optimal heat circulation while securely containing parts. The baskets are manufactured to withstand extreme temperatures ranging from -180°C to 1200°C, making them suitable for diverse heat treatment processes including annealing, quenching, and tempering. Their robust construction incorporates advanced metallurgical principles, utilizing materials such as stainless steel, nickel alloys, or heat-resistant steel grades that maintain structural integrity under thermal stress. The design often includes reinforced bases, sturdy handles, and stackable features to maximize furnace space utilization. These baskets play a crucial role in maintaining part organization, preventing damage during handling, and ensuring uniform heat distribution across all components. They come in various sizes and configurations to accommodate different part geometries and batch sizes, with some featuring customizable compartments for specific applications. The baskets also incorporate drainage systems for quenching operations and are designed for compatibility with automated handling systems in modern heat treatment facilities.