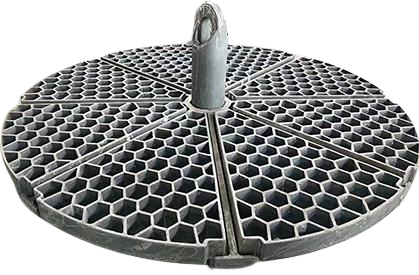

precision sand casting

Precision sand casting represents a sophisticated manufacturing process that combines traditional sand casting methods with modern precision engineering techniques. This advanced casting method utilizes specially prepared sand molds created through precise pattern making and sophisticated molding techniques to produce high quality metal components. The process begins with the creation of a highly accurate pattern, typically made from wood, metal, or plastic, which is used to form the mold cavity in special sand mixtures bound with chemical additives. The sand mixture is carefully controlled for grain size, moisture content, and binding properties to ensure optimal mold integrity and surface finish. During the casting process, molten metal is poured into the prepared sand mold under controlled conditions, allowing for the production of complex geometries with tight tolerances. The method excels in producing components ranging from small intricate parts to large industrial castings, offering dimensional accuracy typically within ±0.005 inches per inch. This versatility makes precision sand casting particularly valuable in industries requiring high quality components with complex internal passages, varying wall thicknesses, and specific mechanical properties.