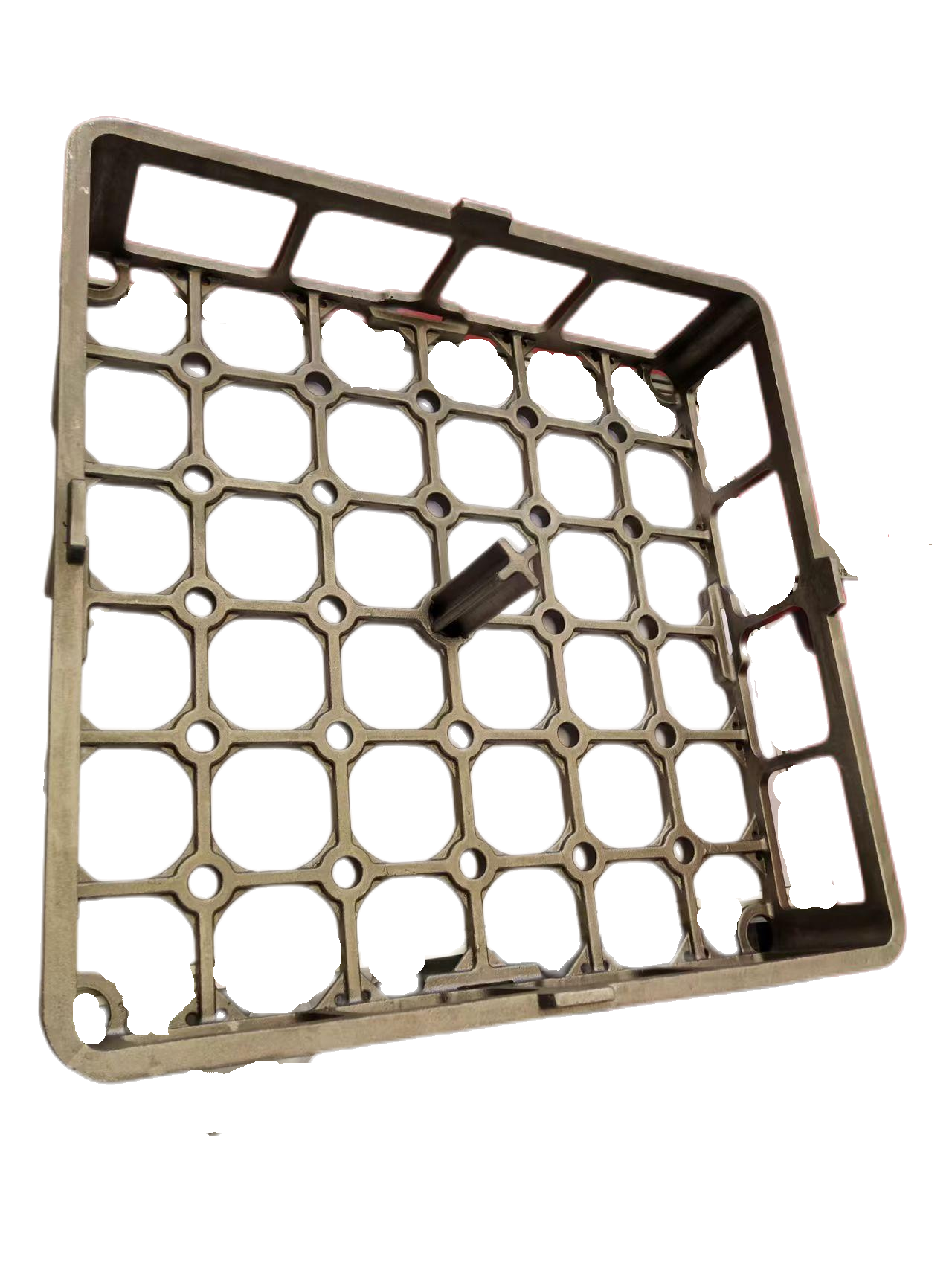

engineered precision castings

Engineered precision castings represent a sophisticated manufacturing process that combines advanced engineering principles with traditional casting methods to produce highly accurate metal components. This technology utilizes computer aided design (CAD), simulation software, and precise process control to create complex parts with exceptional dimensional accuracy and surface finish. The process begins with detailed material selection and engineering analysis, followed by the creation of precise molds that incorporate advanced gating and feeding systems. These castings are manufactured under strictly controlled conditions, with temperatures, pressures, and cooling rates carefully monitored to ensure optimal metallurgical properties. The technology enables the production of components with intricate geometries, uniform wall thickness, and superior mechanical properties that would be difficult or impossible to achieve through conventional manufacturing methods. Applications span across various industries, including aerospace, automotive, medical devices, and industrial machinery, where components must meet rigorous performance standards. The process offers significant advantages in terms of material utilization, reduced machining requirements, and the ability to produce near net shape parts that require minimal post processing operations.