precision investment casting

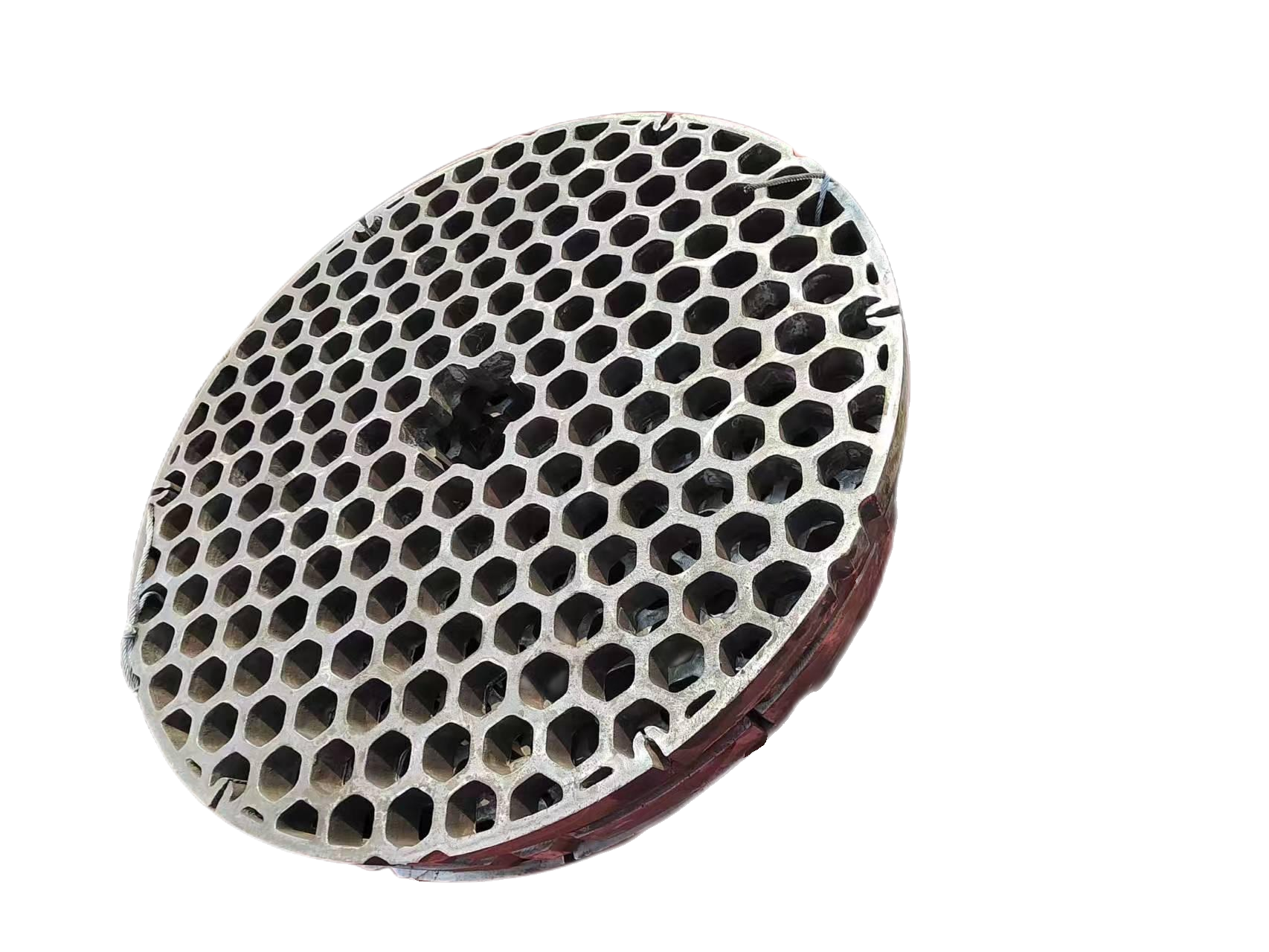

Precision investment casting, also known as lost wax casting, represents a sophisticated manufacturing process that enables the production of complex metal parts with exceptional accuracy and surface finish. This method begins with creating a wax pattern of the desired component, which is then coated with ceramic material to form a shell. Once the ceramic hardens, the wax is melted away, leaving a precise cavity that mirrors the original pattern. Molten metal is then poured into this cavity, allowing it to solidify and take the exact shape of the original design. The process excels in producing intricate components with tight tolerances, smooth surfaces, and fine details that would be difficult or impossible to achieve through conventional manufacturing methods. This versatile technique finds extensive applications across various industries, including aerospace, automotive, medical equipment, and industrial machinery. The ability to cast a wide range of metals and alloys, combined with the capability to produce both small and large components, makes precision investment casting an invaluable manufacturing solution for complex, high-precision parts that require consistent quality and dimensional accuracy.