lost foam casting manufacturers

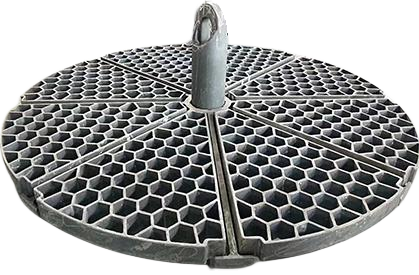

Lost foam casting manufacturers specialize in a sophisticated casting process that utilizes expandable polystyrene foam patterns to create complex metal components. This innovative manufacturing method begins with the creation of a precise foam pattern that exactly replicates the desired final product. The pattern is coated with a refractory material and embedded in unbonded sand. During the casting process, molten metal is poured onto the foam pattern, causing it to vaporize and perfectly replace the void with metal. This technology allows manufacturers to produce intricate parts with exceptional dimensional accuracy and surface finish. Lost foam casting manufacturers employ advanced equipment and quality control systems to ensure consistent production of high-quality castings across various metals, including aluminum, iron, and steel. The process is particularly valuable for producing components with internal passages, undercuts, and complex geometries that would be difficult or impossible to achieve with traditional casting methods. These manufacturers serve diverse industries, including automotive, aerospace, marine, and heavy equipment sectors, providing cost-effective solutions for both prototype and high-volume production runs.